|

|

|

Pad Printing DIY

Plate Making Kit |

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the printing plate (cliché)

via a silicone pad onto a substrate (surface to be printed). Pad printing is used for printing on otherwise impossible

products in many industries including medical,

automotive, promotional, apparel, electronics, appliances, sports

equipment and toys. It can also be used to deposit functional

materials such as conductive

inks, adhesives, dyes and lubricants. |

|

These cliché

making liquid allows the pad printer to take his film positive

artwork and make inexpensive short run clichés.

|

| 1-Cleaning

liquid 500ml /bottle(011036)

2-Photosensitive liquid

250ml /bottle(011007)

3-Developing liquid 250ml

/bottle(011008)

4-Etching liquid 250ml

/bottle(011009)

5-Stripping liquid

500ml/bottle(011010)

6-5 syringes(001060)

7-2 pieces of thick steel

plate(011006)

cliché-making |

|

How the process works

|

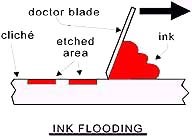

Step 1: Flooding

The image to be

transferred is etched into a printing plate commonly

referred to as a cliche'. Once mounted in the machine, the

cliche' is flooded with ink. The surface of the cliche' is

then doctored clean, leaving ink only in the image area.

As solvents evaporate from the image area the ink's

ability to adhere to the silicone transfer pad increases. |

|

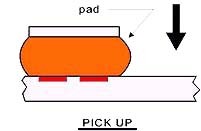

Step 2: Pick Up

The pad is positioned directly over the

cliche', pressed onto it to pick up the ink, and then

lifted away. The physical changes that take place in the

ink during flooding (and wiping) account for its ability

to leave the recessed engraving in favor of the pad.

|

|

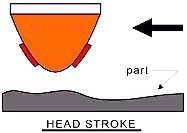

Step 3: Print Stroke

After the pad has lifted away from the

cliche' to its complete vertical height, there is a delay

before the ink is deposited on the substrate. During this

stage, the ink has just enough adhesion to stick to the

pad (it can easily be wiped off, yet it does not drip).

The ink on the pad surface once again undergoes physical

changes: solvents evaporate from the outer ink layer that

is exposed to the atmosphere, making it tackier and more

viscous.

|

|

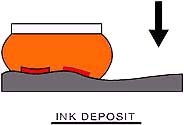

Step 4: Ink Deposit

The pad is pressed down onto the

substrate, conforming to its shape and depositing the ink

in the desired location. Even though it compresses

considerably during this step. a properly designed pad, in

fact, will never form a 0-degree contact angle with the

substrate; such a situation would trap air between the pad

and the part, resulting in an incomplete transfer.

|

|

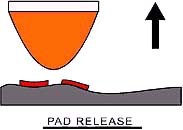

Step 5: Pad Release

The pad lifts away from the substrate

and assumes its original shape again, leaving all of the

ink on the substrate. The ink undergoes physical changes

during the head stroke and loses its affinity for the pad.

When the pad is pressed onto the substrate, the adhesion

between the ink and substrate is greater than the adhesion

between the ink and pad, resulting in a virtually complete

deposit of the ink. This leaves the pad clean and ready

for the next print cycle.

|

|

|

Items included:

1) 2 sheets thick steel plate (011006)

2) 1 Cleaning liquid 500ml /bottle (011036)

3) 1 Photosensitive liquid 250ml /bottle(011007)

4) 1-Developing liquid 250ml /bottle(011008)

5) 1-Etching liquid 250ml /bottle(011009)

6) 1-Stripping liquid 500ml/bottle(011010)

7) 5 syringes(001060) |

|