|

|

新建网页 1

|

Full-automatic Double-position Heat Transfer Printing Machin(Pneumatic) |

|

This Pneumatic Double Table Heat press

machine is featured by its two working tables and air automatic

working system. The upper heating board

moves automatically and easily. It is very efficient for advertising

use and industry use. Heating panel and

working tables are specially processed and make the machine

works well and tranfer images clearly.

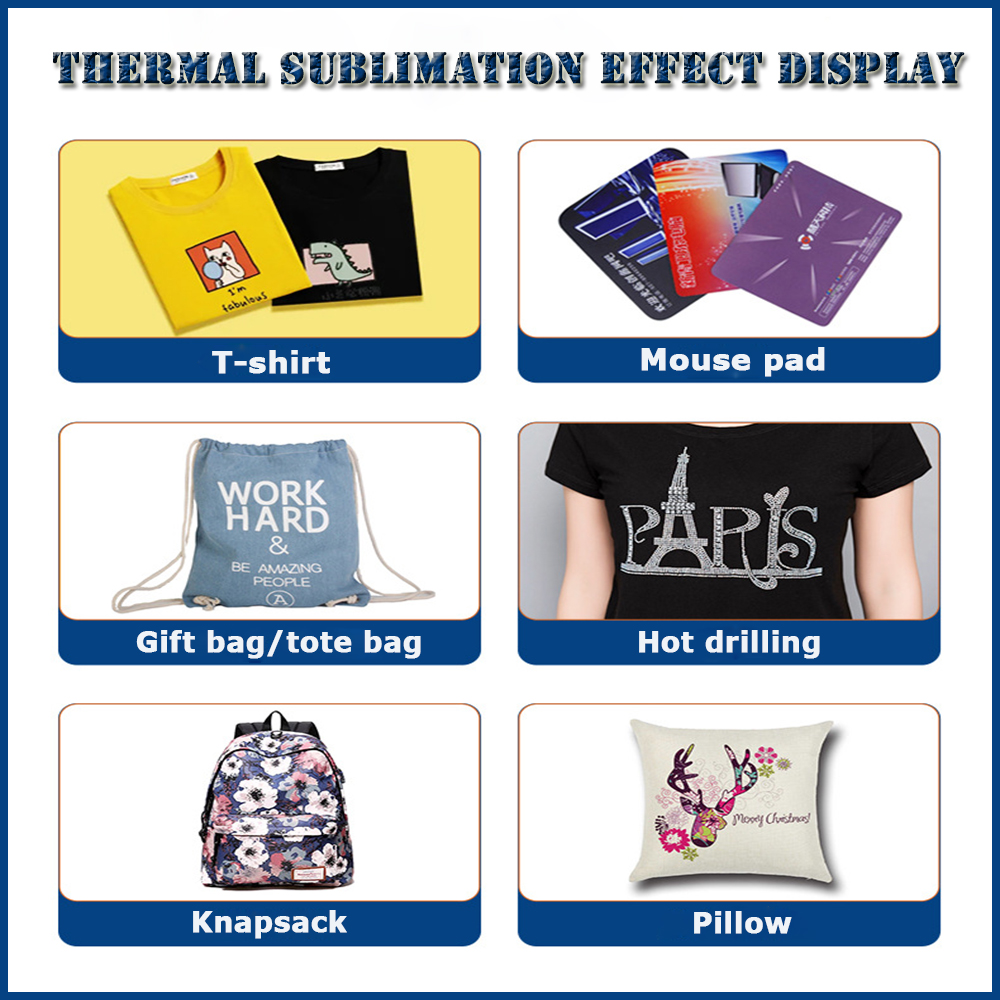

It's suitable for sublimation and heat

transfer printing work. |

|

|

Parameter |

|

Items |

Double-position Heat Transfer

Printing Machine(Pneumatic) |

|

Printing Area(mm) |

400*500mm(15.7*19.7inch) |

|

Temp.range |

0-260°C |

|

Time Range(s) |

0-999 |

|

Votage/Power |

110V/2.5KW |

|

G.W.(kgs) |

228KG(502lbs) |

|

Machine Dimensions(mm) |

1100*700*550(44*27.5*21.6inch) |

|

Packing Size (mm) |

125*86.7*148.5(49.2*34.1*58.5inch) |

|

|

Feature |

|

1.High quality as well as good price, good after-sale

service.

2.The machine adopted

automatic

pneumatic fitting pressure, it can transfer the lower pressure to higher

compress pressure. (pressure up to 8kg/cm2).

3.It

contains two locations, paralleled moving the head up left and right,

much more convenient and faster,

high efficiency ,save labor and time at one time.

4.This machine adopts thicken heat plate to ensure the

temperature more equality and steady as to

improve the transfer quality and avoids tolerance.

high accuracy, perfect heat press effect.

5.Upgraded

lower platen allows room for T-shirts to be easily, placed into and

removed from machine,

10cm adjustable range,

produce wider products.

6.The

pressure can be adjusted according to the thickness of the material

you're transfering to. Including

print the ready made clothes and cut pieces ,it can be

widely used in the factory mass-production and

personalized pyrograph of retail shops. |

|

|

|

|

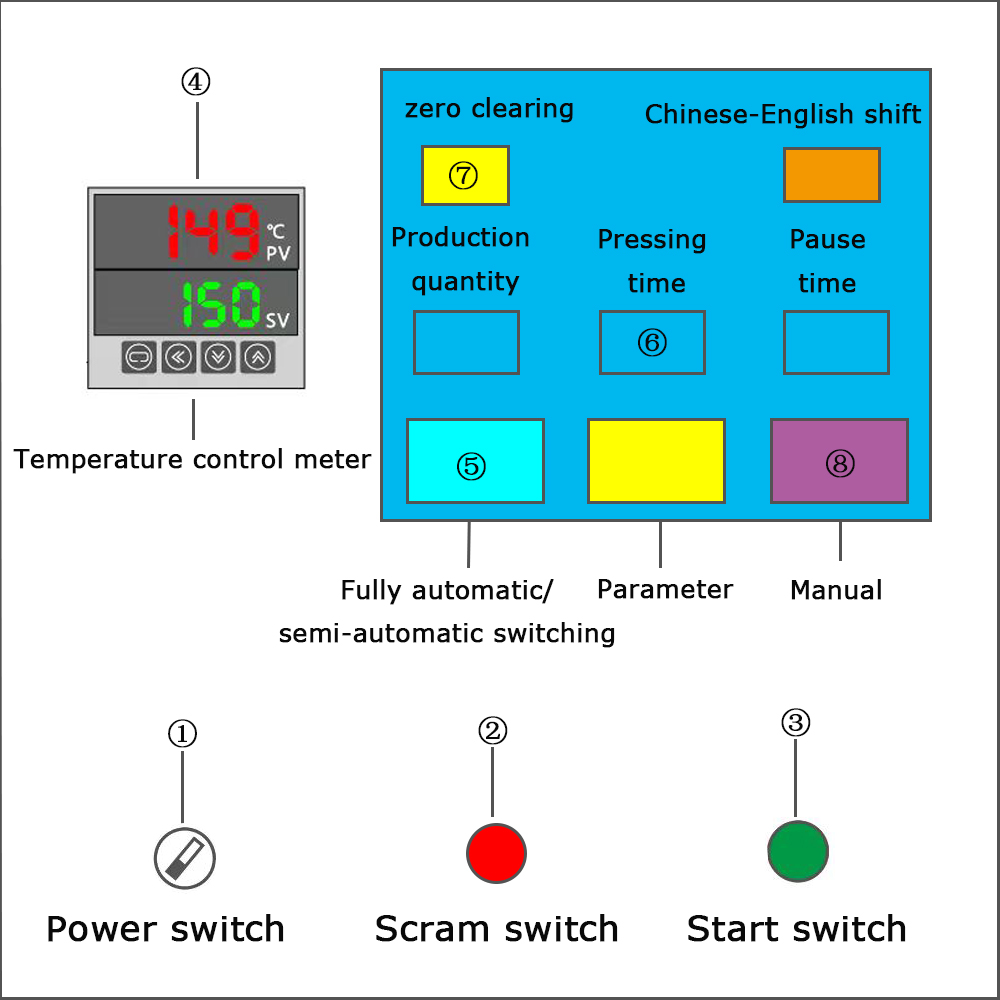

1.Power switch key: turn off the machine

power when flipping left, turn on the machine power when

flippingright.

2.Emergency stop key: When pressing

this key, the heating plate stops pressing, and the heating plate

canpress normally when it springs up.

3.Start key: When pressed, the heating plate will start the heating plate action according to the set mode.

4.Temperature control table:Press to set the temperature, press to set the temperature, press to adjust the value, and press to adjust the value, and press

again to

confirm the temperature. again to

confirm the temperature.

5.Automatic semi-automatic

switch:Automatic press mode, press the start key once, the heating

platerepeated left and right action

and press down. Semi-automatic push down mode, press the start key

once,heat plate action and push

down once.

6.Pressing time: the heating plate

can be set a single pressing time.

7.Reset: can clear the produced

quantity value.

8.Adjustment operation: Enter the

adjustment interface first press the "motor brake" key, turn

greenbackground can be controlled

by the other three keys to move the heating plate to the left, to

the right

tomove a single press work.

|

|

|

Operation procedures |

|

Please

note: Users should operate the machine with ground wire connected for

safety!

1.Plug in, turn on the power switch, the power indicator

lightened.

2.Set the thermostat to the temperature needed (Normally

120-200ºC),set the timer to the needed. (Normally 5~20Second),then wait

for until the temperature has reached the preset temperature.

3.Put

the cloth on the silicone pad of the working table,

cover the printing paper (please note the right

surface of the paper).

4.Press the start switch, you will see the machine is

working and the time is counting down

.

5.When the time come down to over,

the heating plate will raise automatically.

you will find the beautiful

and attractive effect!

6.If it is cold-ripping of the transfer paper, please use

blackboard wiper to rub against the whole transfer paper, wait for 5-10

seconds, then rip off the transfer paper. If it is the hot-ripping of

the transfer paper,

you can rip off immediately after printing. |

|

Please

note:successful print requires right time,temperature and pressure,the

thickness of the

clothes material

,even thetype of printing paper,all will affect the performance of

printing .Any

kind of

sublimation paper need test before mass production. |

|

Item Number: 110162 |

|

|

You can make

order with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us

with low cost. |

|