|

|

CNC

| 5L Double Arm Z Blade Mixer stainless steel 220V |

| This equipment is designed for kneading and mixing high-viscosity elastic materials including rubber, silicone rubber, food-grade adhesives and agents. The machine is characterized by a horizontal twin-shaft configuration with dual-speed operation under atmospheric pressure, and achieves manual cylinder rotation for material transfer and manual cylinder lid control. Due to the operation at atmospheric pressure, the machine enhances indoor hygiene, reduces physical strain, and boosts production efficiency. |

|

Specification :

Input voltage:220V 50/60Hz 1PH

Motor Power:1.5KW

Heating Power: 0.8kw*3

Funnel capacity:5L

Funnel material: 304 Stainless steel

Rotational speed:Variable frequency control Without a plug |

|

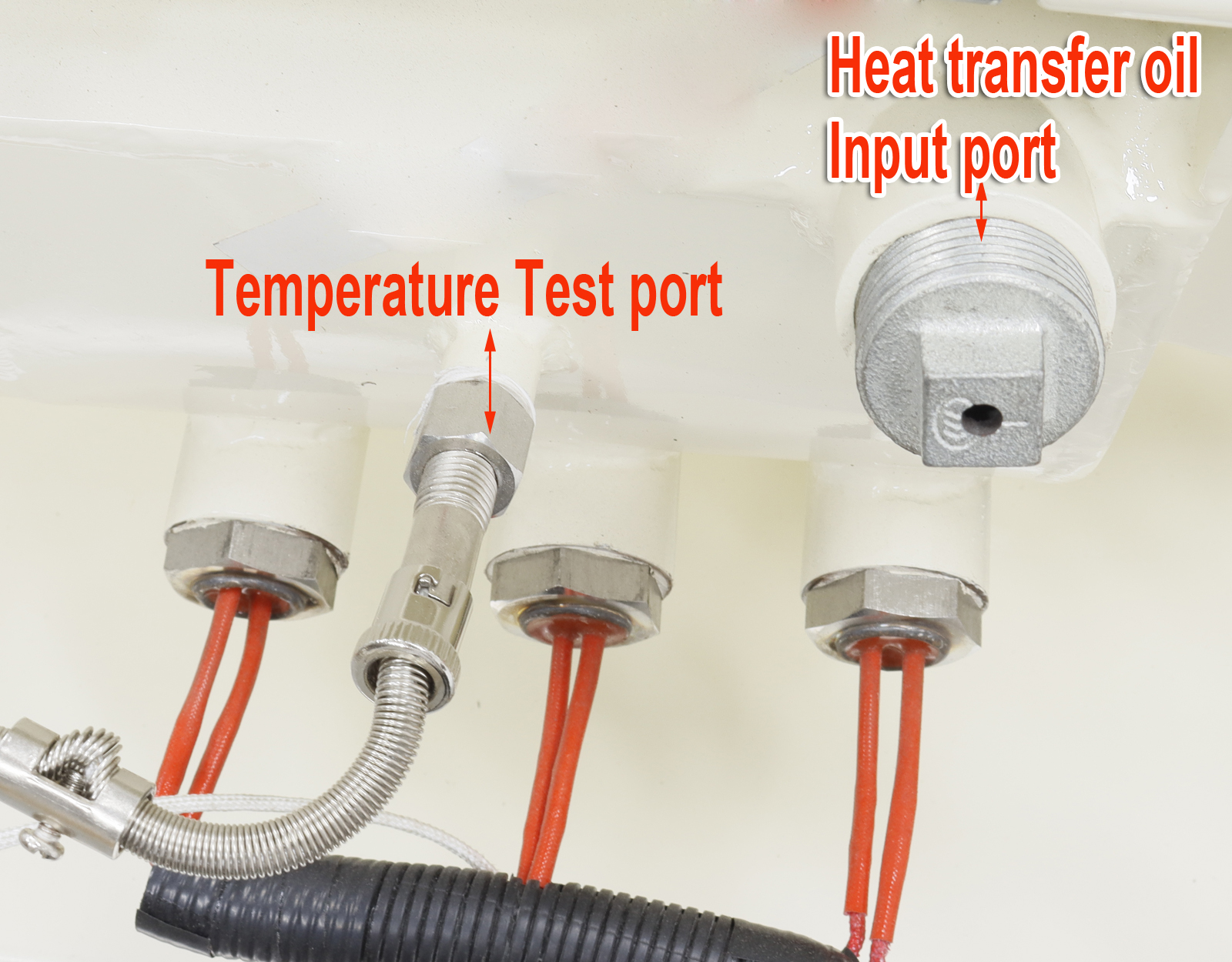

Temperature Test Port & Heat Transfer oil Input Port |

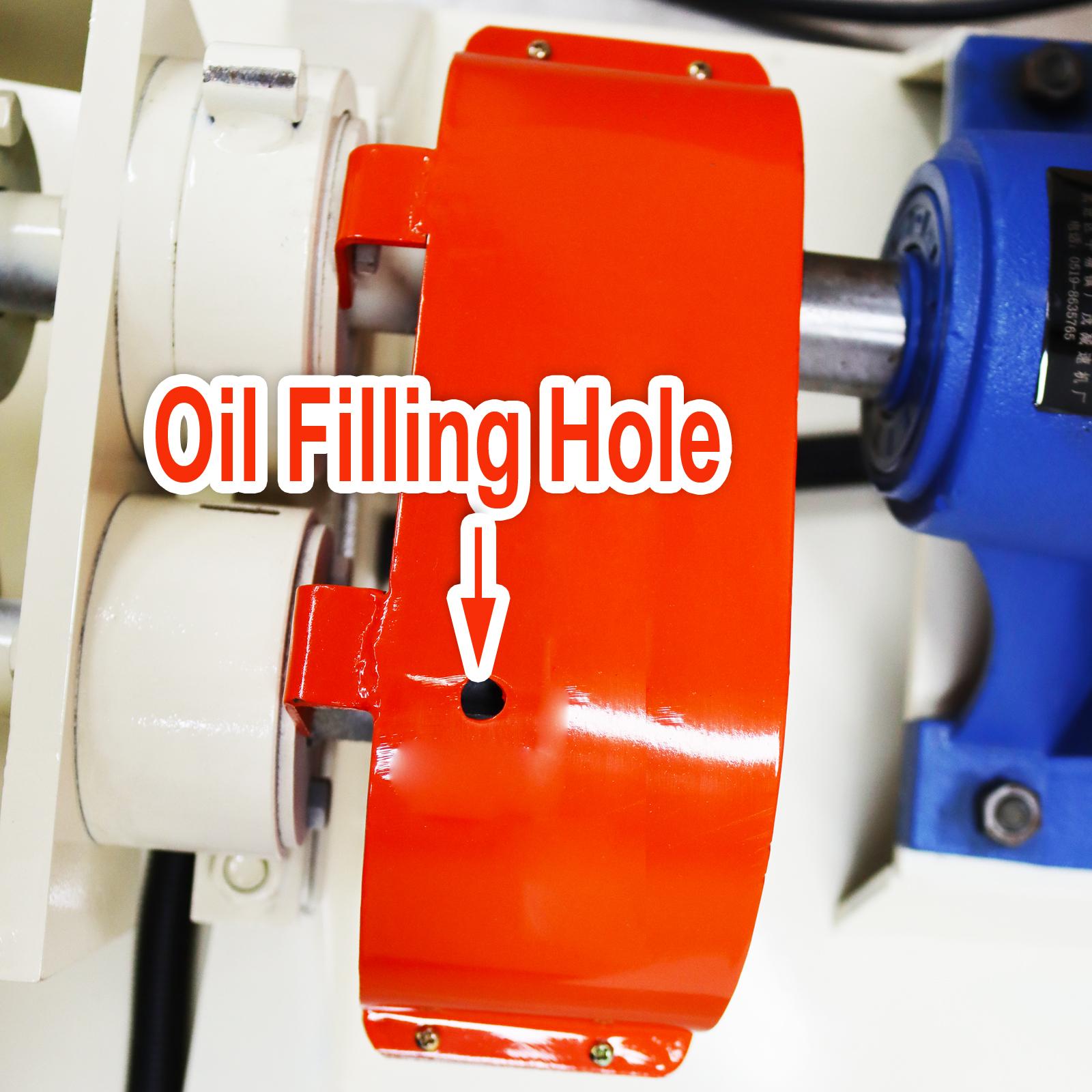

Oil Filling Hole,

Gear lubricant must be added before using the machine. |

|

|

Control Panel |

| The Tail Positioning Bolt |

|

|

Lid & Fixing Bolts |

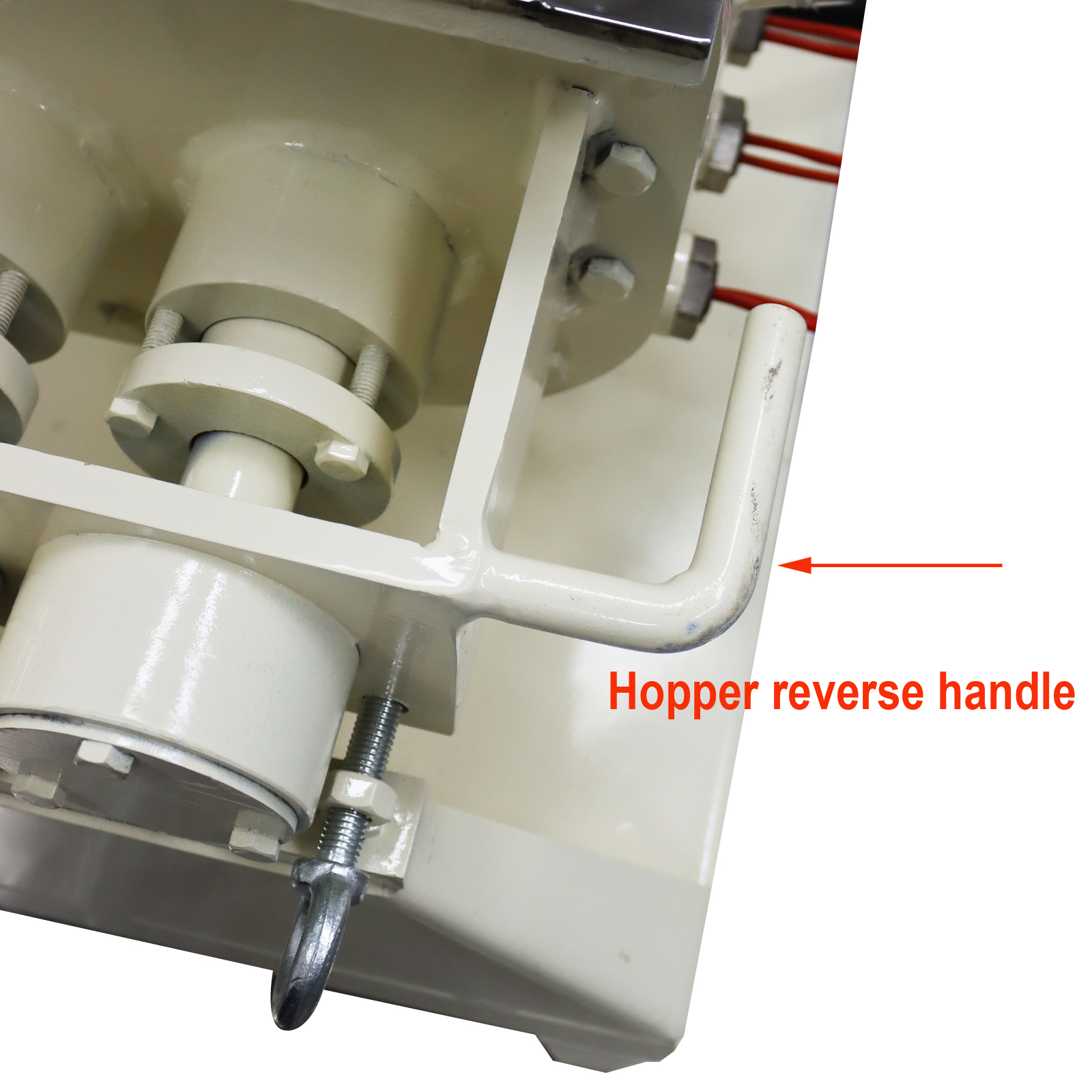

| Hopper reverse handle |

|

|

Double-Shaft Mixing |

Installation and debugging :

1-This machine is a small test device which can be placed on the ground or workbench.

2-Connect the power supply and check whether the motor is rotating forward.(220V 50/60hz)

3-After equipment installation, check whether bolts in all parts are loose, verify if there is any leakage after the machine is powered on, inspect whether transmission systems operate normally, observe mechanical transmission performance, and confirm the rotation direction of dual shafts. The inward rotation direction is considered standard. When it is found that there is no abnormalities after no-load operation is conducted for 30 minutes, the equipment can proceed to trial production.

4-Precautions for adding thermal oil: At the first time, add the thermal oil to the temperature measurement point to heat and stabilize the expansion of thermal oil. If there is no overflow, continue to add a small amount of thermal oil. Add a small amount of thermal oil for several times to avoid expansion and overflow of thermal oil.

5-Tighten the tail positioning bolt and do not reverse it during operation.

6-Gear lubricant must be added before using the machine.

7-Clean the funnel thoroughly.

8-Add materials to the hopper.

9-Close the lid and tighten the fixing bolts on it.

10-Start the main mixing motor and close the bin lid. During mixing, activate the heating function with preset temperature settings. When conditions permit, open the bin lid to monitor material changes.

11-Normal shutdown:

Stop the host; Manually flip the tank over and pour the materials out;

Reversely discharge the materials; Clean the remaining glue in the tank after shutdown.

|

Warning:

-Read carefully and understand all INSTRUCTIONS before operating the machine.Failure to follow the safety rules and other basic safety precautions may result in serious personal injury.

-The machine should not be filled with too much heat transfer oil. Please add the appropriate amount of heat transfer oil.

-Gear lubricant must be added before using the machine.

-Always keep children away from this machine, PROHIBIT children from operating the machine.

-Never touch the RUNNNING Parts or insert hard ware into the machine.

-Always unplug the machine when assembling or disassembling the unit.

-Never insert hands inside the entrance.

-Press the On/Off switch once to turn on or turn off the machine. Pressing the buttons for multiple times may damage the machine.

-Moisture of the machine during transportation may cause some internal parts to rust, which will not affect the use.

-The part in contact with the Materials is made of 304 stainless steel.

-Each batch may have small improvements as the product needs to evolve. |

Item included:5 L Double Arm Z Blade Mixer stainless steel 220V*1

Item Number: 134103 |

| You can make order with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in normal condition.

Handling Time: Shipping is usually made in 1-3 business days after payments cleared. Orders are processed from Monday-Friday; Not on the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty period has expired, you can still seek for service or technical support from us with low cost. |

|