|

Handheld Pneumatic

Strapper |

|

This

tool is a kind of fusion packaging machine. The

lapped thermoplastic packaging belt is fused by the heat produced by

friction motion; hence, it is called "friction fusion". Principle is to

use the binding tape winding product or package, then tighten and ends

by heating molten or use the material such as bag buckles connection

machine. |

|

|

|

Product parameter: |

|

|

Drived:: |

by air pump |

|

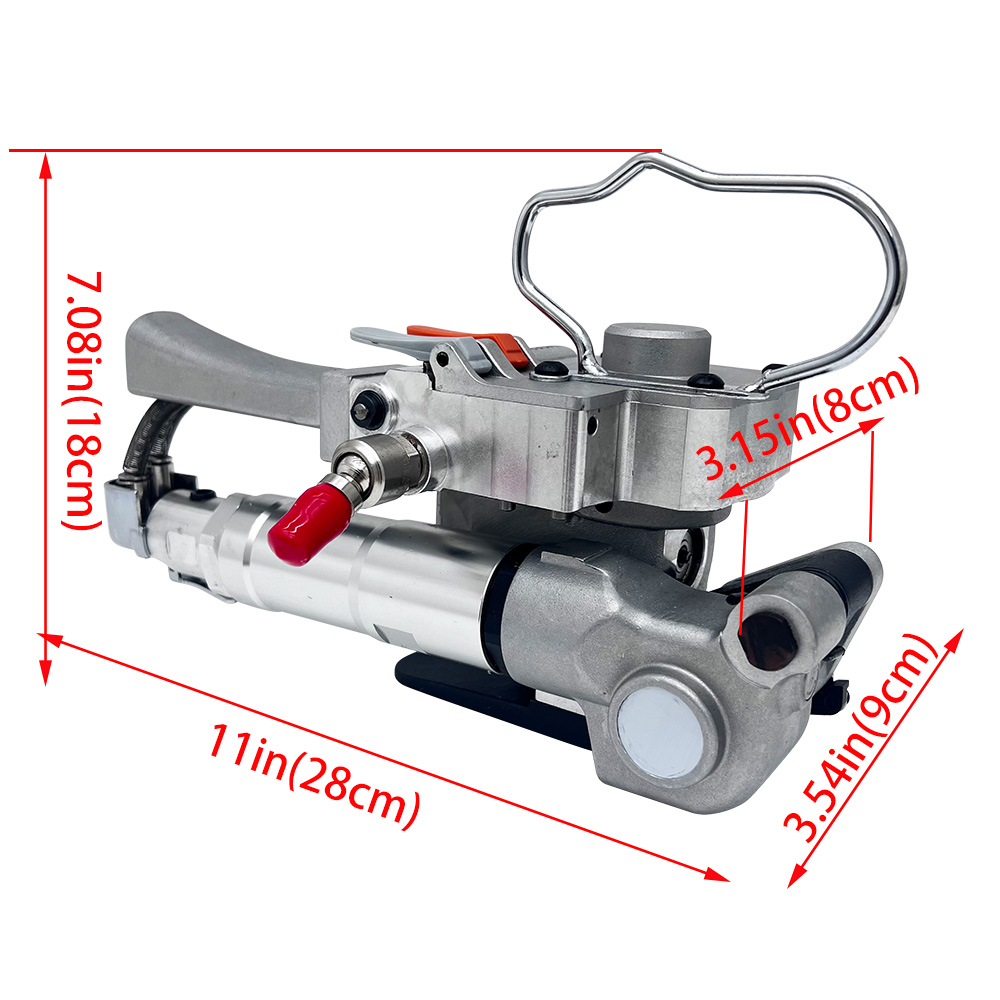

Size:

|

11*3.54*7.08in(28*9*18cm) |

| Air pressure: |

0.5-0.8Mpa |

| Max strap tension Max: |

3500N |

| Strapping material: |

Polyester |

| Applications: |

PET strap, PP band |

|

Function: |

Tensioning+Sealing+Cutting |

| Strapping width: |

13mm(1/2")-19mm(3/4") |

|

Strapping thickness: |

0.5(0.0196")-1.5mm(0.06") |

| Weight: |

3.8kg(8.37lb) |

|

|

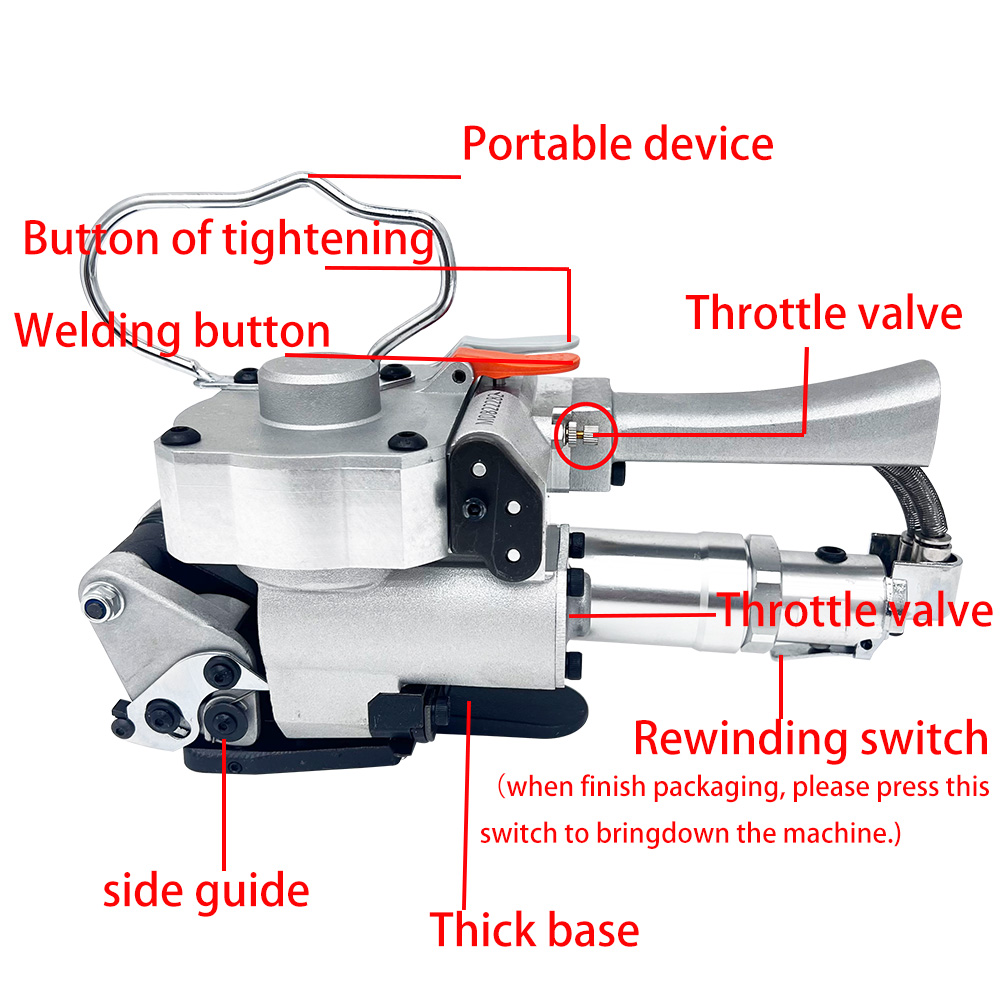

Product Analysis: |

|

|

|

Feature: |

|

|

The lightweight body makes the use of

equipment more convenient and greatly improves safety performance. |

|

Humanized handheld design

Portable handheld design, convenient for carrying out, suitable for

packaging large objects. |

|

|

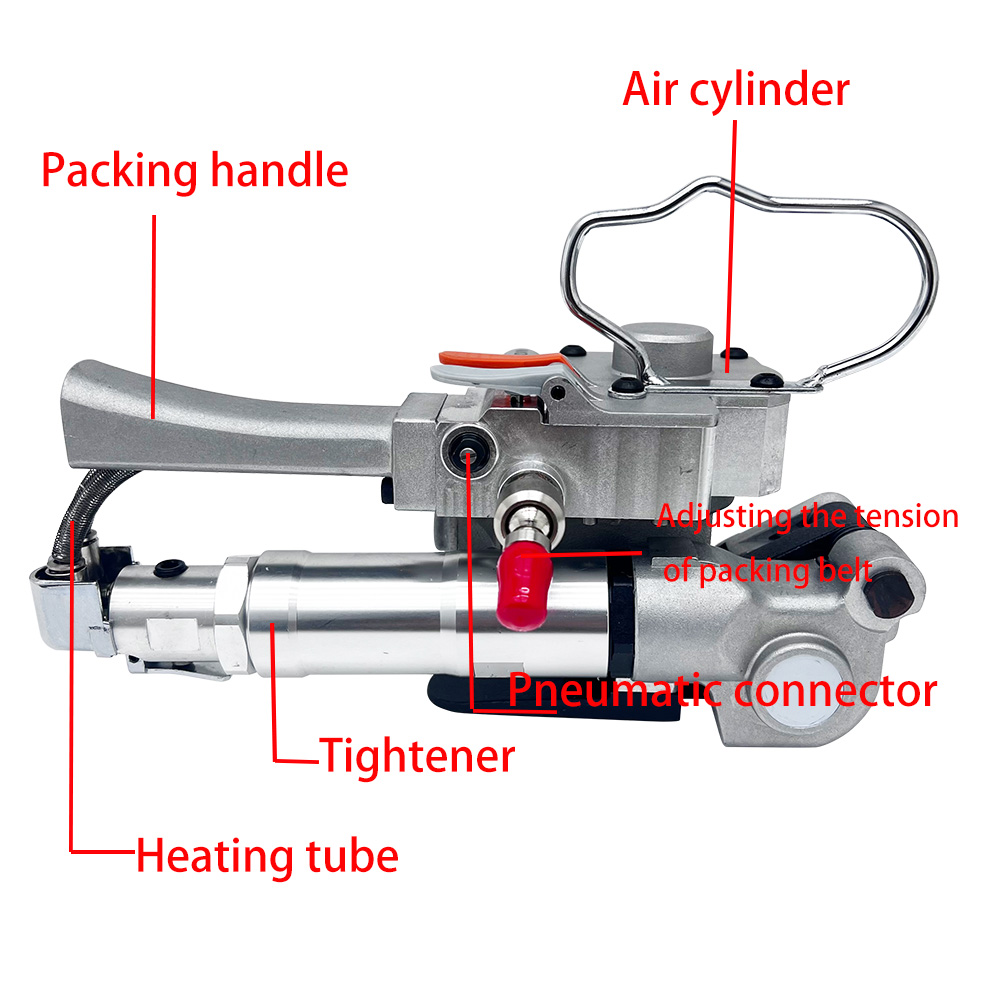

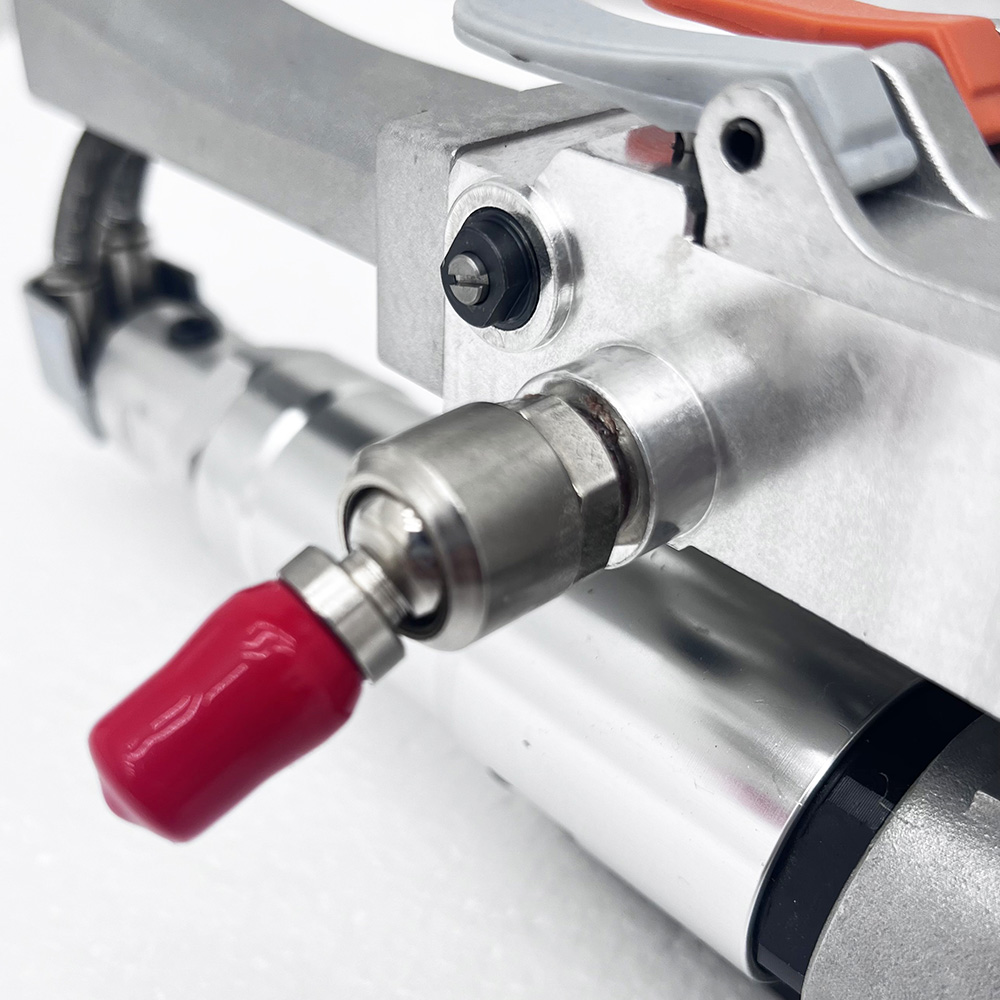

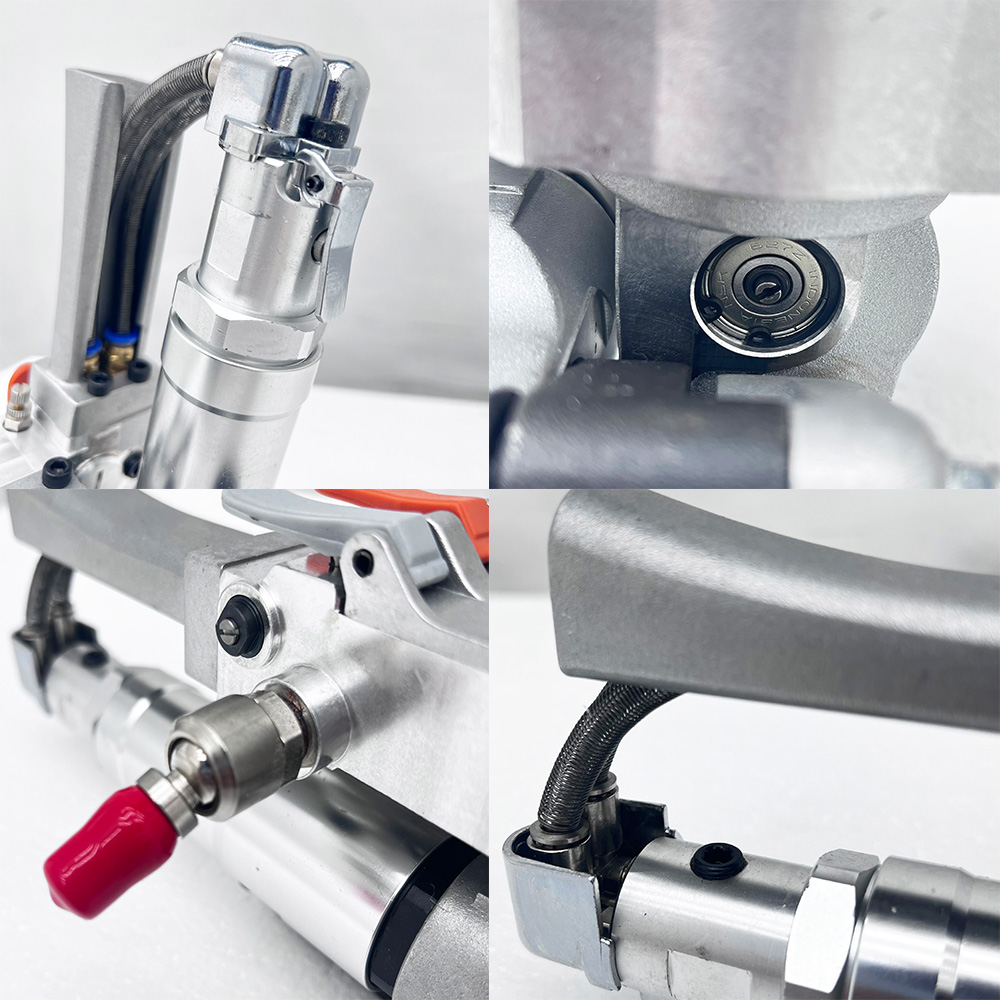

Gas pipe quick connect

connector

The air pipe must be connected to the air pump for gas supply. The

packaging joint is a metal type, wear-resistant, and has a long service

life.(Red is the protective cover)

|

Easy packaging operation

Press and hold the tension button with your right thumb until the

packaging tape is completely tightened, and then press and hold the

fusion button until the packaging tape blows. |

|

|

|

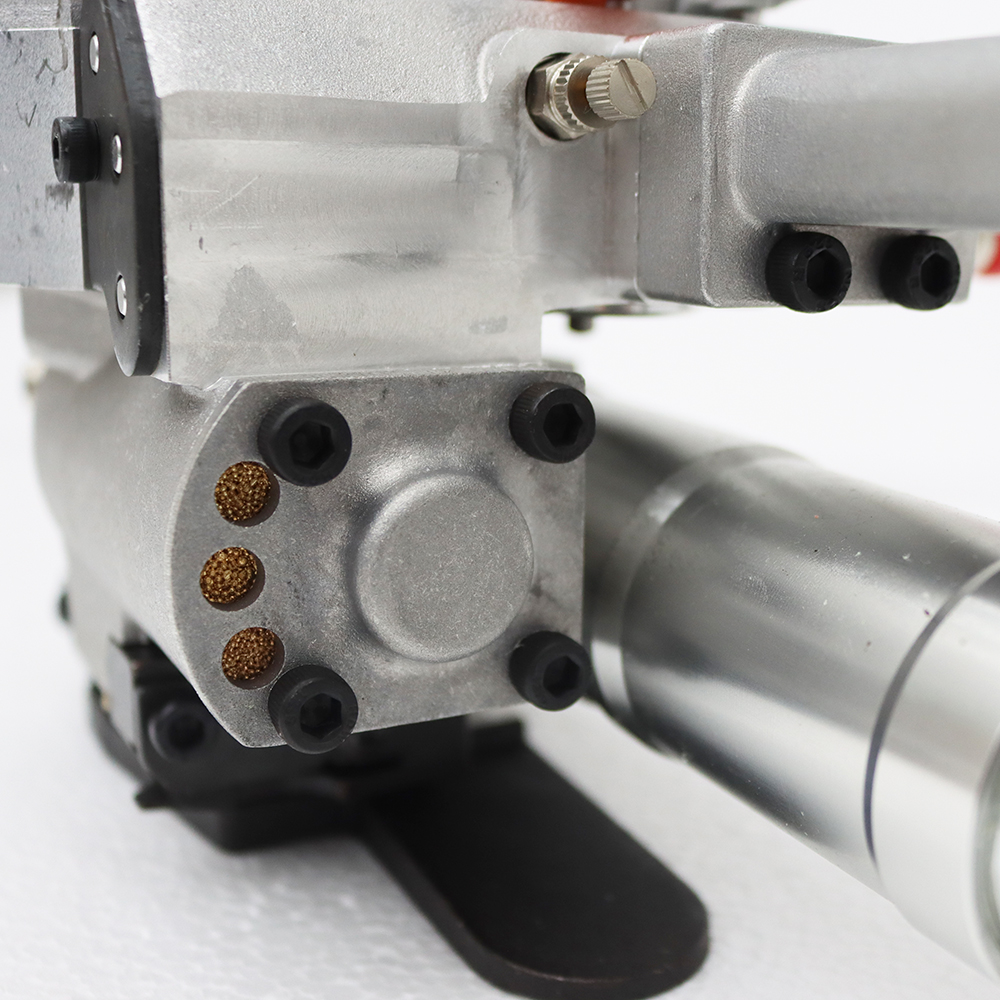

Silencing device

In order to keep the machine quiet during operation, this machine is

equipped with special noise reduction equipment (note: after the air

pump is filled with air, the machine is used without noise). |

Rewind button

After packaging is completed, press the rewind button with your right

little thumb until the packaging belt is sent down from the tensioning

wheel, and then remove the packaging machine.

|

|

|

Principle of

Friction Instruction: |

|

1.The compressed air

will push the piston within air cylinder. The upper part of piston and

vibrating bar is connected with the rocking pin, so the vibrating bar

will press the lapped part of packaging belt when moving down.

2.There is an elliptic

hole at the center of vibrating bar. This hole is connected with the

eccentric shaft of pneumatic motor. The pneumatic motor rotates at a

high speed (10000rpm), so the vibrating bar conducts reciprocal motion

quickly. The lower part of packaging belt is fixed by the peg teeth of

fusion toothed plate, and its upper part is driven by the peg teeth of

vibrator for strenuous friction. Hence, the lapped part of packaging

belt is fused by the heat produced by friction. When the vibration timer

reaches the set time, vibration stops and fusion completes.

3.Both upper and lower

parts of the packaging belt are stuck while extruding. |

|

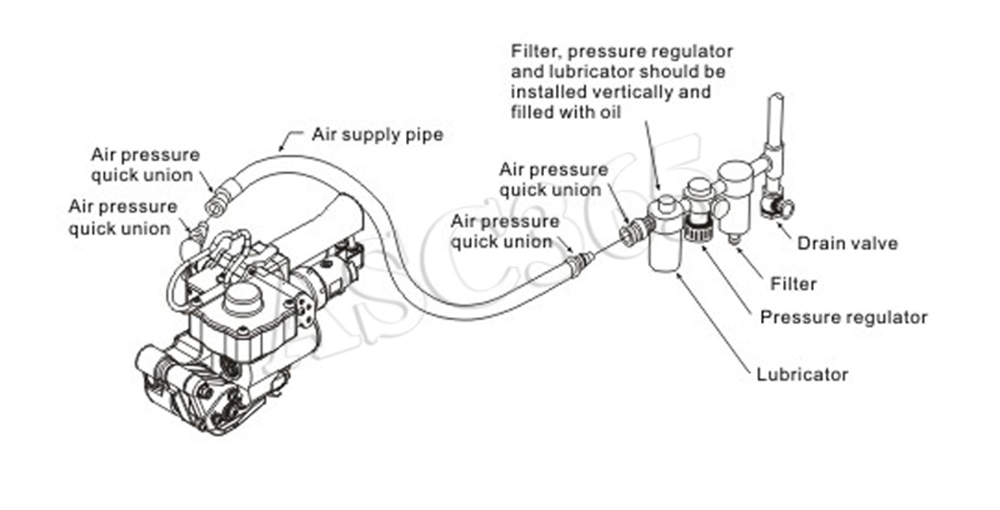

Gas Source

Instruction: |

|

Requirement of air pressure

The required scope of air pressure: (5.0-7.0bar)

Installation of gas source

Filter, pressure regulating valve and lubricator assembly shall be close

to the pneumatic tool. The min. inner diameter of air hose is

6.0mm(1/4). Both ends of air supply pipe should be equipped with quick

unions.

Moisture filtration

A drain valve must be mounted at the bottom of the air supply circuit's

bypass to drain once every day.

Lubrication

Pneumatic motor should be lubricated properly, and the lubricator should

be full and well regulated (a drop every 2min). |

|

|

Product

safety precautions: |

To ensure safe production, please read the

following precautions carefully:

1.Bear in mind

"safety-foremost" principle, and operate this pneumatic tool properly;

2.Read the Manual carefully

before operation;

3.Don't dismantle safety

parts of the tool;

4.Don't tear or damage label

or mark of the product;

5.Don't put hand or other

part of your body between packaging belt and packaging tool.

|

|

Details: |

|

|

|

|

|

Product display: |

|

|

|

|

|

Item include:Handheld

Pneumatic Strapper*1 |

|

Item Number: 151030 |

|

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |