|

|

新建网页 1

|

Portable Skid Resistance Tester 154003 |

|

.jpg) |

|

Product Introduction

The skid resistance tester is

used to determine friction coefficients of road surface, airport

runway, marking paint, etc., and to determine the friction

coefficients of typical road surfaces to provide a basis for various

tire compounds. The tester is characterized by convenient debugging,

simple operation, less impact on traffic during measuring, more

stable data, and usage in both indoor and outdoor circumstances. |

|

Item specifics

Usage: Abrasion Tester

Rocking torque:615000g.mm

Weight of the

pendulum: 1500g(3.3lb)

Gravity

moment of the pendulum: 410mm(16.1inch)

Scale distance: 508mm

Forward static

pressure from rubber sheet to pavement:2263g(5lb)

Distance between

rocking center to rubber sheet outer edge:508mm(20inch)

Net

weight:14kg(30.9lb) |

|

|

|

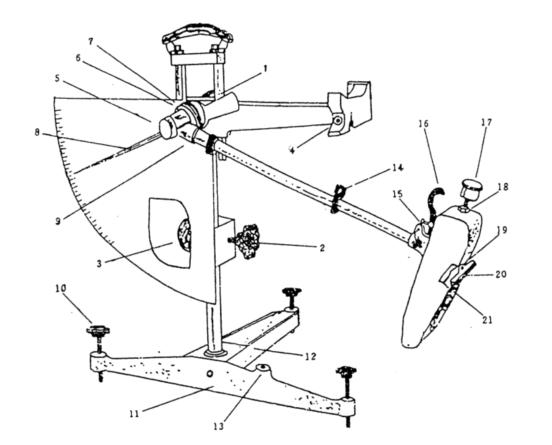

1. Fixing handle 2

& 3 Lifting handle 4. Release switch

5. Steering stem

cap 6. Adjusting screw 7. Needle reed 8. Pointer

9. Connecting

screw 10. Level screw 11. Base support

12. Level bubble

13. Snap ring 14. Positioning screw 15. Lifting handle

16. Balance hammer

17. Fixing screw 18. Sliding block

19. Rubber sheet

20. Anti sliding screw |

|

Main Components

1. Base support:

comprised of T shape leg, leveling screw and level bubble, it’s used

for level and support purpose;

2. Column:

comprised of column, lifting mechanism, guiding rod, handle, used

for lifting and fix the head;

3. Release switch:

installed on the pendulum rod, used for keeping the rod horizontal

position and to release the pendulum;

4. Steering

system: comprised of fixing handle, pendulum shaft, steering

knuckle, bearing, it’s used to keep the pendulum can freely swing

within the plain;

5. Indicating

system: comprised of pointer felt coil, pressing cap, pointer

adjusting screw and scale plate, pointer can directly indicate the

value;

6. Pendulum head:

comprised of upper lower connector, pendulum rod, spring, lever,

lifting handle, hammer shell, slider, rubber

piece(76mm*25.4mm*6.35mm), it has specific torque to the swing

center, also specific pressure to the pavement.

|

|

.jpg) |

|

Operation

Instruction

Select points

On the test pavement, along with the left wheel

running direction, choose 5 representative points, each point apart

by 5-10m.

Leveling

Place the tester on the test point, let the swing

direction same with the car running direction;

Rotate the leveling screw to let the level bubble in

middle position.

Zero setting

1)Pointer position

calibration: let the pendulum in perpendicular status, dial the

pointer to let the upper part closely contact the adjusting screw,

now the pointer pointing position should align to the pendulum rod

center position, otherwise should adjust the adjusting screw to let

the pointer align with the pendulum rod center position, after

adjusting should fix the screw thus to fix the pointer adjusting

screw position;

2)Release fixing

handle, rotate the lifting handle to lift the pendulum and let it be

in freely swing status, then screw the fixing handle;

3)Let the pendulum

move to right, let the positioning snap ring enter into the on-off

slot, let the swing rod locate in horizontal release position,

meanwhile, dial the pointer by left hand to let it closely contact

the screw on the needle dialer;

4)Press the

release switch then pendulum will swing to left, and drive the

pointer to move upward, when pendulum move to the highest position

then drop, catch the pendulum rod by left hand, now the pointer

should be in zero point, if not, can fasten or release the pointer

adjusting screw till the pointer is in zero point.

Sliding distance calibration

1)Use rubber brush

to clean the test area of pavement;

2)Let pendulum

freely hang, let the ruler center align to the pendulum rod, let the

sliding ruler parallel to the test direction and close to the rubber

sheet;

3)Release the

fixing handle, rotate the lifting handle to let the pendulum fall

slowly and meanwhile let the pendulum to move to right, place slider

on ruler right side and let it contact pavement surface and align to

the ruler scale, then let the pendulum move to left, and place slide

on left side and let it contact pavement surface and align to the

ruler scale, then screw the fixing handle and recheck the sliding

length, during this process can perform fine adjustment of the

sliding length by leveling screw, let the sliding length keep within

126±0.5mm, note that the level bubble should in middle position

during regulation.

Test procedure

Spray some water

on pavement, then use rubber brush to brush the road of the mud,

then spray water again, and press the release switch to let the

pendulum slide on the surface, pointer will then indicate the

pendulum value(generally first time not record); when pendulum swing

back to right, catch the pendulum rod by left hand, lift the slider

by right hand, and let the pendulum move to right, let the

positioning snap ring enter into release switch, repeat the

operation and test 5 times(every time should spray water) and record

each time value, the difference in 5times shall not over 3 units, if

not, should check and find out the reason.

Test result

1) Each point

takes the average value of 5 tests as the friction coefficient;

2)The friction

coefficient is calculated by the pendulum value to divided 100, if

the pendulum value is 33, then the coefficient is 33/100=0.33.

|

|

Noted matters

1.Due to the

friction coefficient is influenced by whether and temperature, so

should record the test date and pavement temperature when testing;

2.Should record

the pavement structure type, appearance, period of operation;

3.When pendulum

move to left and return, shall catch the rod to avoid to damage the

slider and pointer;

4.Within the

sliding range shall not have obvious convex and concave shape;

5.When calibrate

the Sliding length, should subject to when the rubber is just

contact the surface, should not slide forward by the pendulum force,

otherwise the calibrated sliding length will have error;

6.To indicate the

most harmful condition of the road, should choose the part with

lower coefficient and frequent brake, that’s just the left wheel

along the running direction.

7.When use new

rubber sheet, should firstly test on dry road for 10times then test

on wet road for 20times, then can be used. Rubber sheet abrasion

long side not surpass 3.2mm, short side not over 1.6mm, otherwise

should replace with new one. And if the rubber sheet was polluted

should not use again. The rubber sheet effective lift is 12months,

shouldn’t use again regardless it was used or not. Because the

rubber will aging, the elastic and hardness will change thus will

effect the test result.

Maintenance &

Storage & Transportation

1.It’s kind of

precision instrument, users should protect it from any damage

otherwise may effect the test accuracy, before operation should read

the user manual carefully and get familiar with the instrument

structure and operation method. It’s not allowed to uninstall the

instrument at will except the flexible or the removeable part.

2.After operation,

clean the instrument and stored into the case, place it in the room

with good ventilation, no acid, no corrosion.

3.During long

distance transportation, the instrument should be kept in case, no

sudden impact or over shake during transportation.

4.Should be

calibrated at least once every year under normal condition

|

|

Item Include |

|

Portable Skid

Resistance Tester154003 |

.jpg) |

|