|

|

新建网页 1

新建网页 1

|

Dent Pulling

Machine 220V |

|

|

|

|

|

|

|

|

|

Aluminum Dent Pulling

Machine 220V |

|

|

|

|

|

|

|

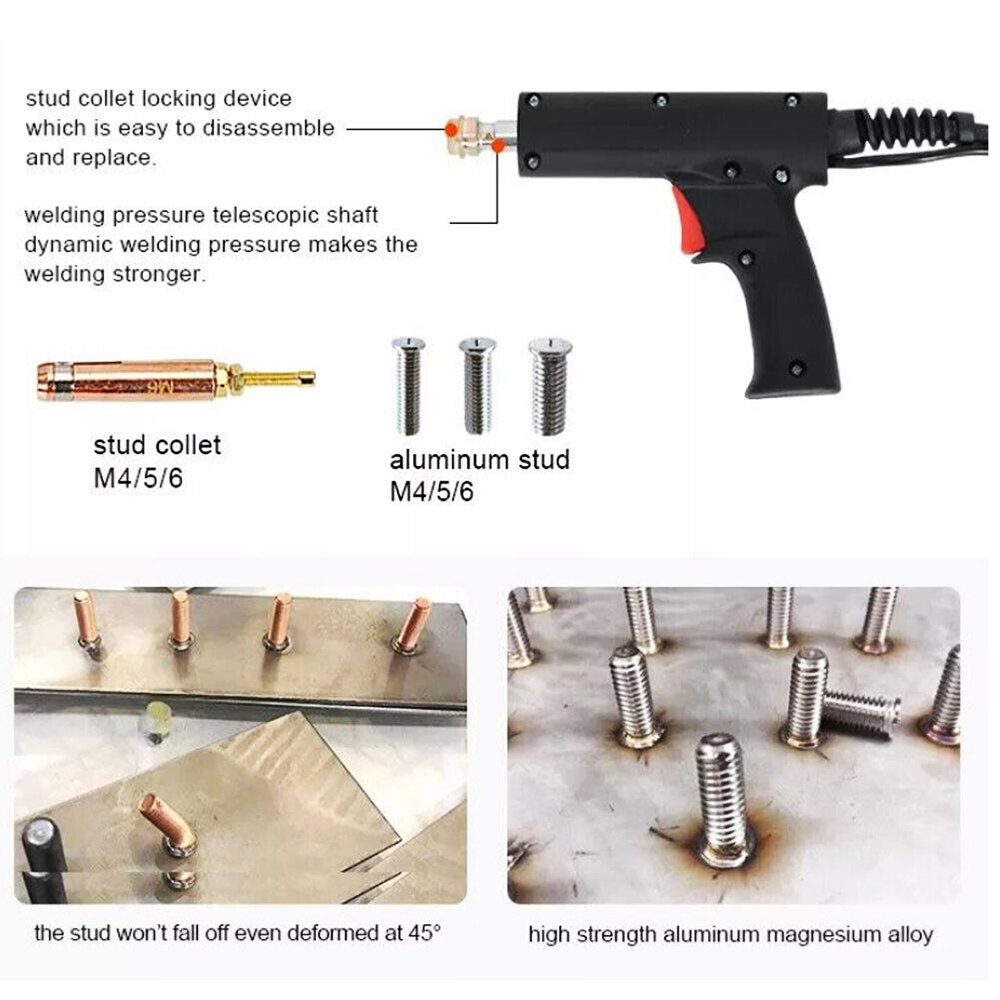

This welding machine can weld studs of various

materials of M3-M6. It hasmany advantages such assimple operation, short

welding time, little heat impact on the base material, no damage to the

basematerial surface, good welding quality, firmness, beautiful

appearance, and energy saving. lt is the most ideal equipment especially

in the maintenance of aluminumcar bodies. |

|

Product parameter: |

Voltage:220V

Instantaneous current:11000A

Rated power:1.5KW

Screw size:M3/4/5/6

Capacitance:12mF |

|

|

Product analysis: |

|

|

Operation method: |

1.First select the appropriate welding tip

according to the size of the stud, adjust the positioning screwin the

welding tip, then insert it into the gun head of the welding torch, and

tighten it carefully with awrench. Then insert the stud to observe, the

stud should be 5-8mm higher than the three supportrods of the welding

torch. Then connect the 220V power supply, and makethe welding machine

reliable grounding. Turn on the power switch, the digital meter displays

thewelding voltage, adjust the "voltage adjustment" knob to the

appropriate voltage according to the sizeof the stud used. The

specifications and voltage matching can be fine-tuned as follows:

| M3 |

M4 |

M5 |

M6 |

| 45V |

70V |

100V |

130V |

|

|

2. Remove oil and rust on the

workpiece to avoid spark splashing or weak welding due to poor contact.

3. The stud is installed in the gun mouth. Make the welding gun

perpendicular to the base material andexerts a slight pressure.

4. Press the micro switch on the handle of the torch, and the welding

will be completed after a "pop".

5. Adjust different voltages and observe the welding effect, subject to

the firmness of the welding andthe welding place is well connected and

flat.

6. Adjust the voltage according to the above experiment results and then

welding.

7. The larger the output voltage, the larger the diameter of the welded

stud.

8. As for the repairing of sheet metal, after welding, screw the pulling

ring on the stud, and use apulling tools with a thermal spray gun to

heat the damaged part and flatten the sheet metal. |

|

|

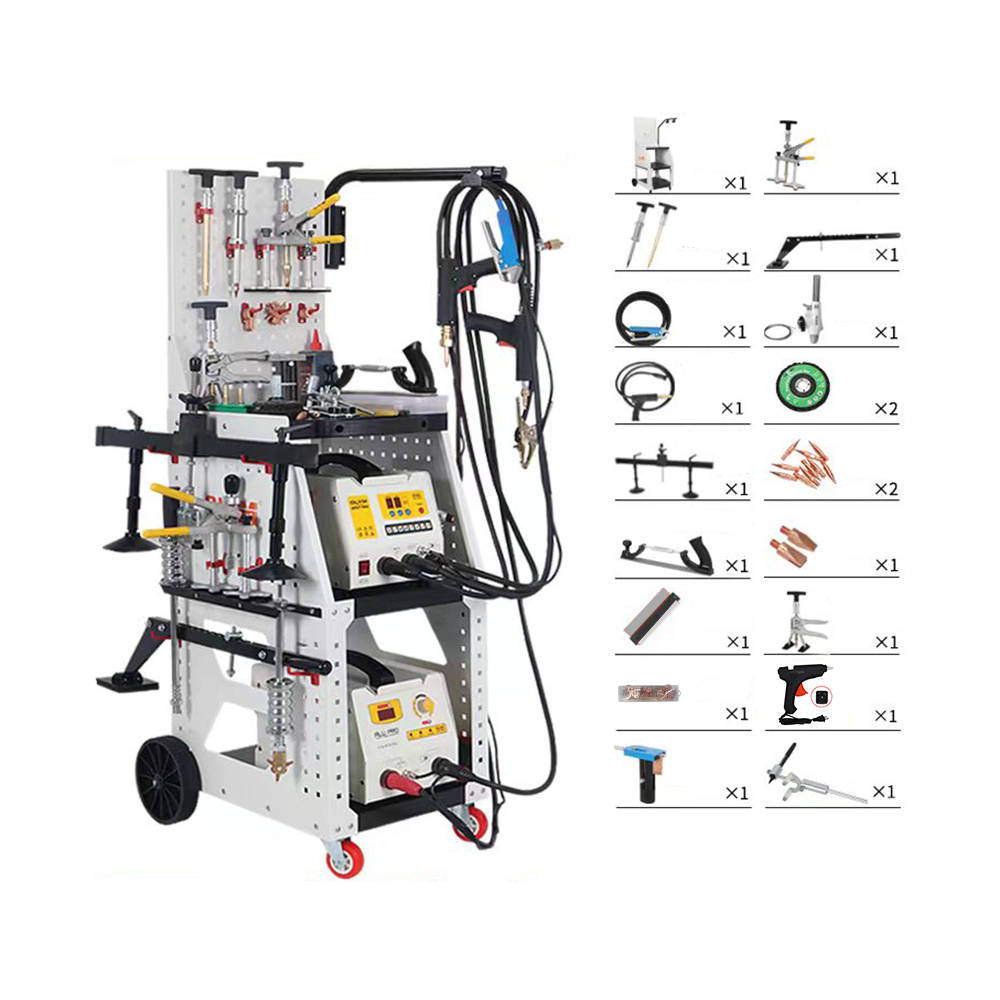

Features: |

|

1. Adjustable pressure welding gun: Different rules of stud required

welding force is different, so the welding gun must be adjustable

pressure.

2. Pull frame aluminum material: more durable.

3. Current knob adjustment: knob adjustment is faster and more

convenient than button adjustment.

4. All copper transformer.

5. Professional workbench: The use of high-strength galvanized plate,

tools more convenient storage.

6. Cable 50m2 oxygen-free copper: discharge current is faster than

double lap iron.

7. Intelligent matching welding mode: fast arcing, deep melting pool,

solid welding.

8.12mF Large capacity capacitor.

|

|

Details: |

|

|

|

Steel Dent Pulling Machine 220V |

|

The

machine is the ideal product for dent pulling and straightening of low

thickness car body elements, such as bonnet, door, roof panel and wings.

This welding machine has many advantages such assimple operation, short

welding time, little heat impact on the base material, no damage to the

basematerial surface, good welding quality, firmness, beautiful

appearance, and energy saving. lt is the most ideal equipment especially

in the maintenance of steel car bodies. |

| Product

parameter:: |

Input Voltage: 220V

Power: 3KW

Welding Thickness: 0.4 to 1.2mm

Instantaneous Maximum Current:6800A

Current: 77 Gears Operation

|

|

| Product analysis: |

|

|

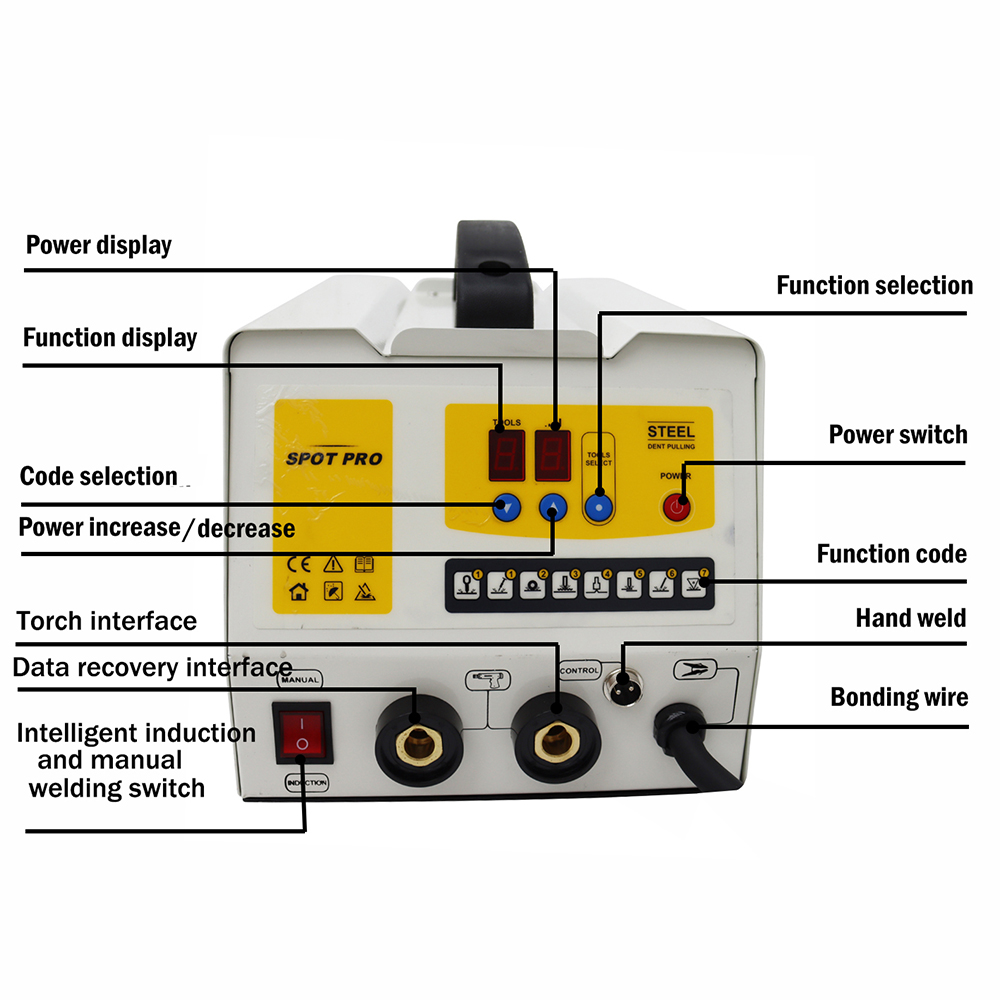

Panel Operation: |

1.Connect the product to a suitable power

source, and then press the switch todisplay: function (left) power

(right).

2.To adjust the power intensity (current size), press the + or - button.

3.To change the function, press the function selection key.At this time,

you can usethe + and - buttons to select the function number.

4.Manual welding and intelligent welding:

---When using manual control, connect the torch switch connector and

switch theswitch to manual mode.

---When using smart mode, there is no need to disconnect the torch

switchconnector and switch the switch to smart mode.

|

Welding Operation: |

| The machine can be welded

manually/automatically, and the host automatically detects the

short-circuit condition of the welding gun, and a welding spot

is generated within 1 second. Disconnect the welding gun and the

welding part for 0.5 seconds, then the next point can be welded,

and others can be welded in sequence. When switches to manual

mode, use the gun switch to control welding. |

|

| Features: |

|

1. Using flexible voltage technology, it can still be welded firmly when

the voltage is low to 155V.

2. The welding joints are extremely small,the consumables loss is small,

no damage to the anti-rust paint behind the sheet metal, less damage to

the original bodywork and stronger welding.

3.Car dent puller has auto welding and manual welding two modes can be

switched at any time, easy to operate.

4. High strength thickened case with thickness up to 1.8mm. |

|

|

|

|

Different places have different Receptacles. Please notee

this plug and consult your electrician before purchase.

|

|

1*

Aluminum+Steel

Dent Pulling Machine 220V (239871) |

| |

|

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|