|

|

|

|

|

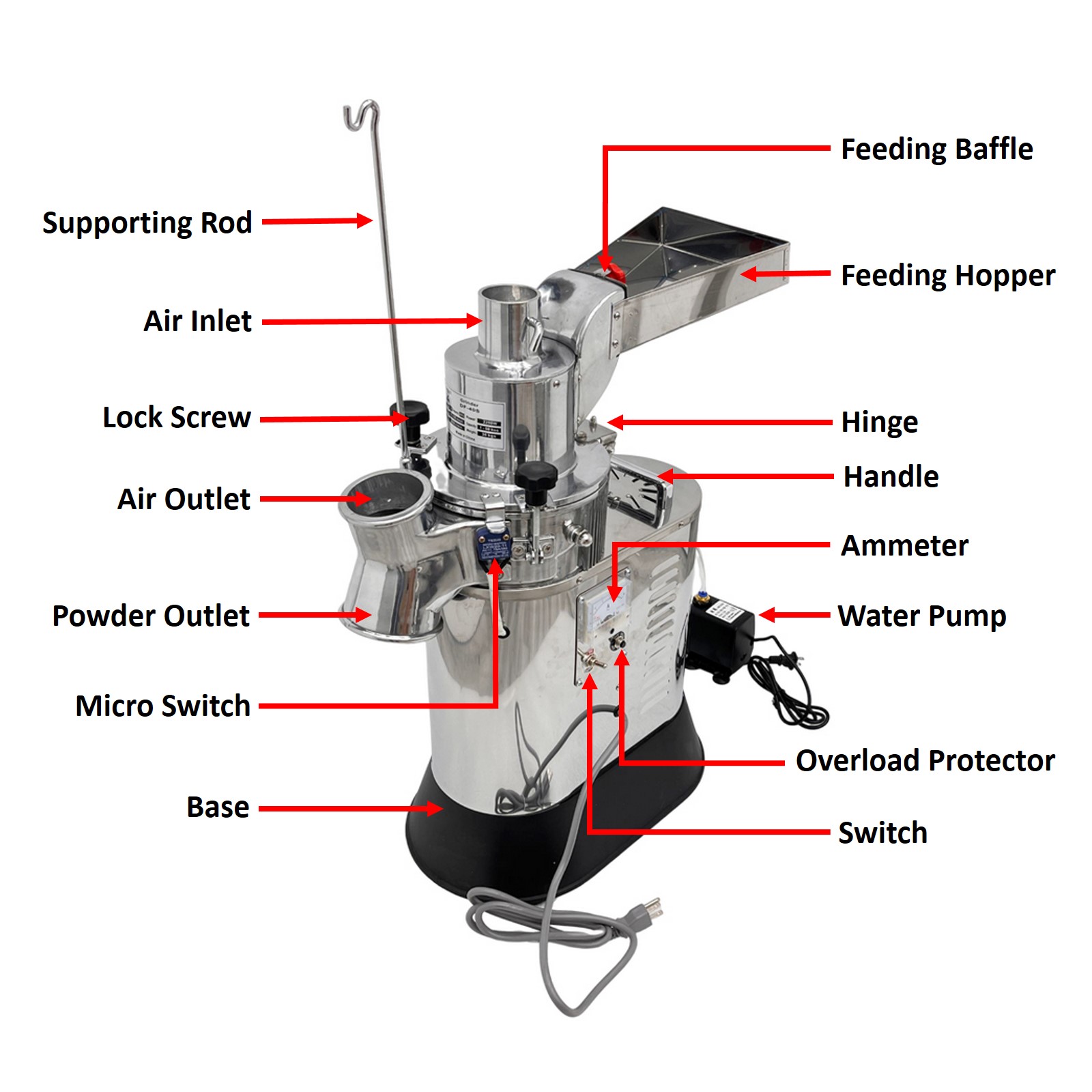

Water-Cooled Continuous

Feeding Grain Mill Grinder 110V 3KW |

|

|

|

|

|

|

|

|

|

Product

Overview |

|

The water cooling type efficient grinder is

a high-quality grinding and smashing device which adopts a water pump

cooling system to reduce the high temperature generated by the grinding

process. The grinder is equipped with different mesh screens to meet

different grinding requirements, can achieve continuous feeding and

efficient grinding operation and has the advantages of having a good

grinding effect, a good water cooling effect and a good air separation

effect and being suitable for grinding various dry materials, such as

salt, coffee, soybean, spice, grain, wheat, pepper and herbs. |

|

Product

Parameters |

| Material |

Stainless steel |

|

Voltage |

110V |

|

Power |

3000W |

|

Fineness |

60-180 meshes |

|

Motor speed |

5600r/min |

|

Output of fine powder |

1-10kg/h (2.2-22.05LB/h) |

|

Output of coarse powder |

1-40kg/h (2.2-88.18LB/h) |

|

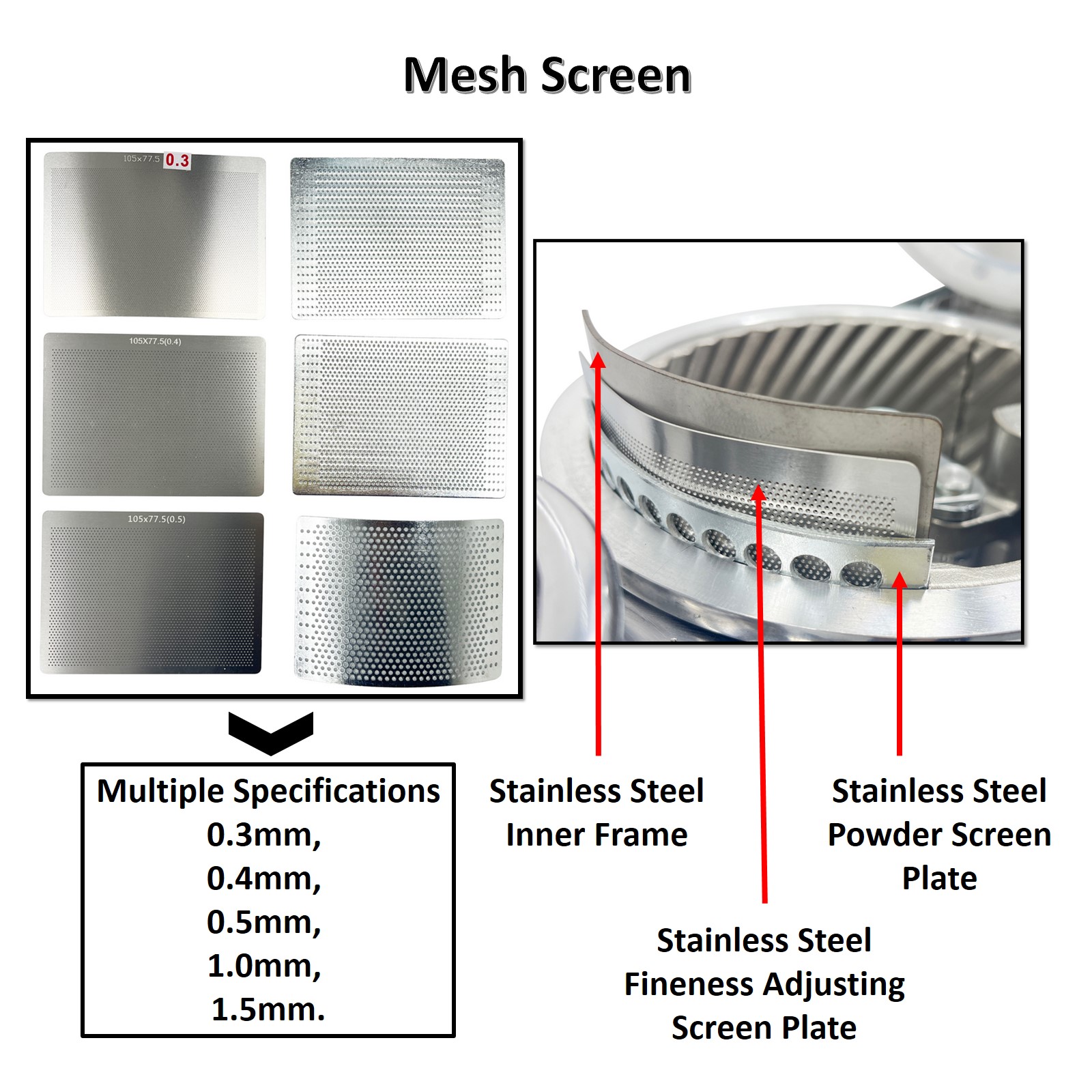

Specification of mesh screens |

0.3mm, 0.4mm, 0.5mm, 1.0mm, 1.5mm |

|

Working time |

Continuous work for 1-5 hours |

|

Product size |

41x25x85cm (16.14’’ x 9.84’’ x 33.46’’) |

|

Net weight |

39KG (85.98LB) |

|

|

|

|

Attention |

|

1. Disconnect the power supply, pull

out the power cord and then open the upper cover of the pulverizer.

There should be no foreign matter in the pulverizing tank. Scrub the

pulverizing tank with medical alcohol for disinfection, and it is

strictly forbidden to directly clean the grinding chamber of the whole

machine with water.

2. After starting the machine, it is recommended to idle for about 1-2

minutes, and then slowly feed the material after the bag is bulged.

3. The raw materials should be dry, slow feeding and slow discharge of

powder should be carried out, and do not feed too many raw materials at

once.

4. Do not grind fresh materials, oily materials or viscous materials. It

is prone to blocking the mesh. If the mesh is blocked, the powder cannot

go out.

5. In order to prolong the service life of the pulverizer, after 2 hours

of continuous operation, the machine should be shut down for 30 minutes

and then restarted.

6. During the use of this machine, it is strictly forbidden to open the

top cover or put your hands, brushes and other tools into the crushing

chamber to avoid mechanical and personal accidents.

7. Do not let children touch or operate the machine to prevent

accidents.

8. If the material sticks to the wall of the crushing bin, it can be

gently scraped with a stainless steel spoon, or wiped with a rag and

alcohol. Do not wash it with water.

|

|

Product

Features |

|

|

|

|

|

|

|

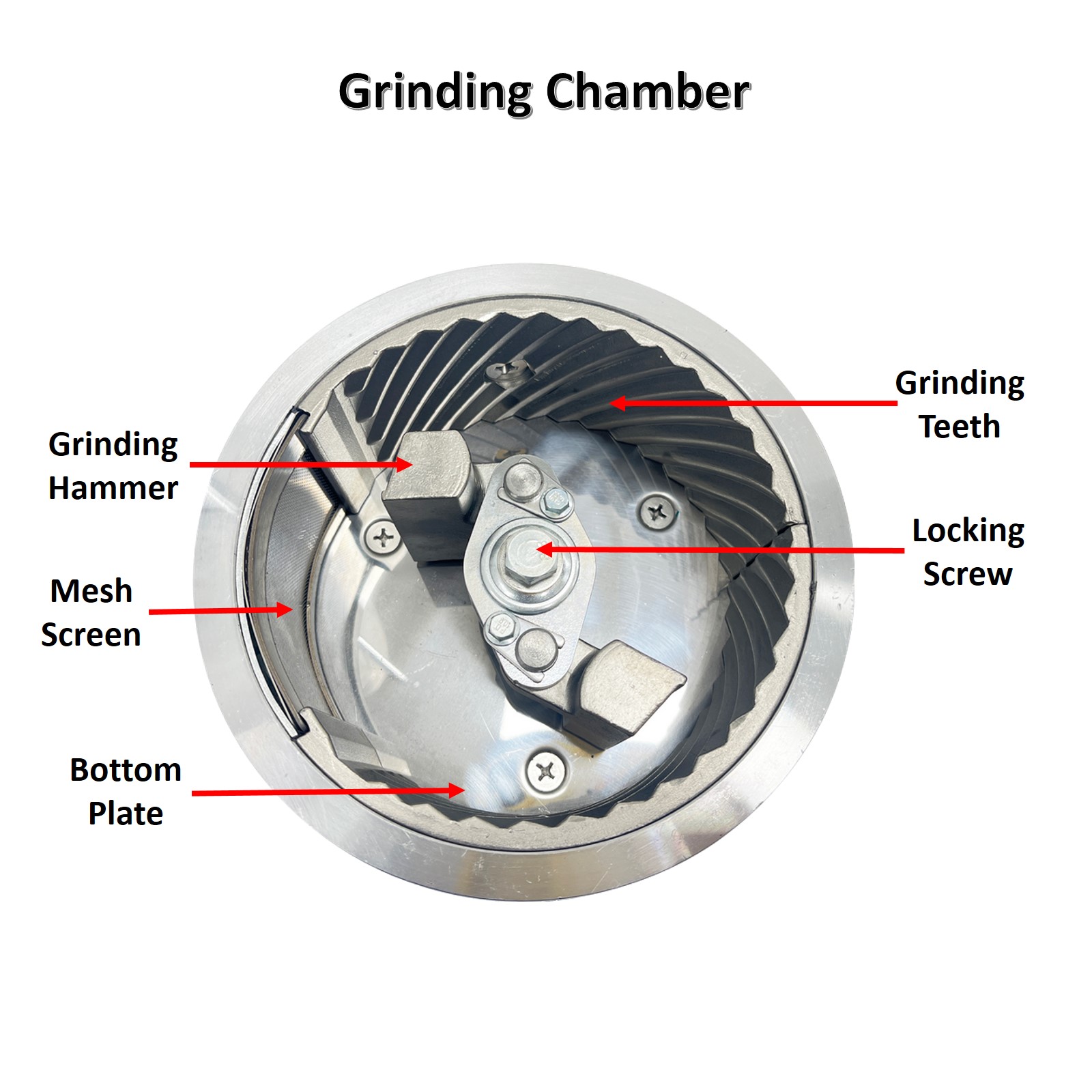

Stainless steel grinding teeth and smashing hammers are

integrated in the grinding chamber, have good attractiveness and

corrosion resistance, are free of hazardous substances and can

cooperate with each other to grind raw materials safely and

effectively, thereby greatly improving the working efficiency. |

|

The grinder is

equipped with 5 kinds of stainless steel mesh screens with

different mesh specifications, the requirements of customers for

fine powder and coarse powder can be well met through

replacement of the mesh screens, the mesh screens are resistant

to wear and corrosion, and the practicability is greatly

improved. |

|

|

|

|

|

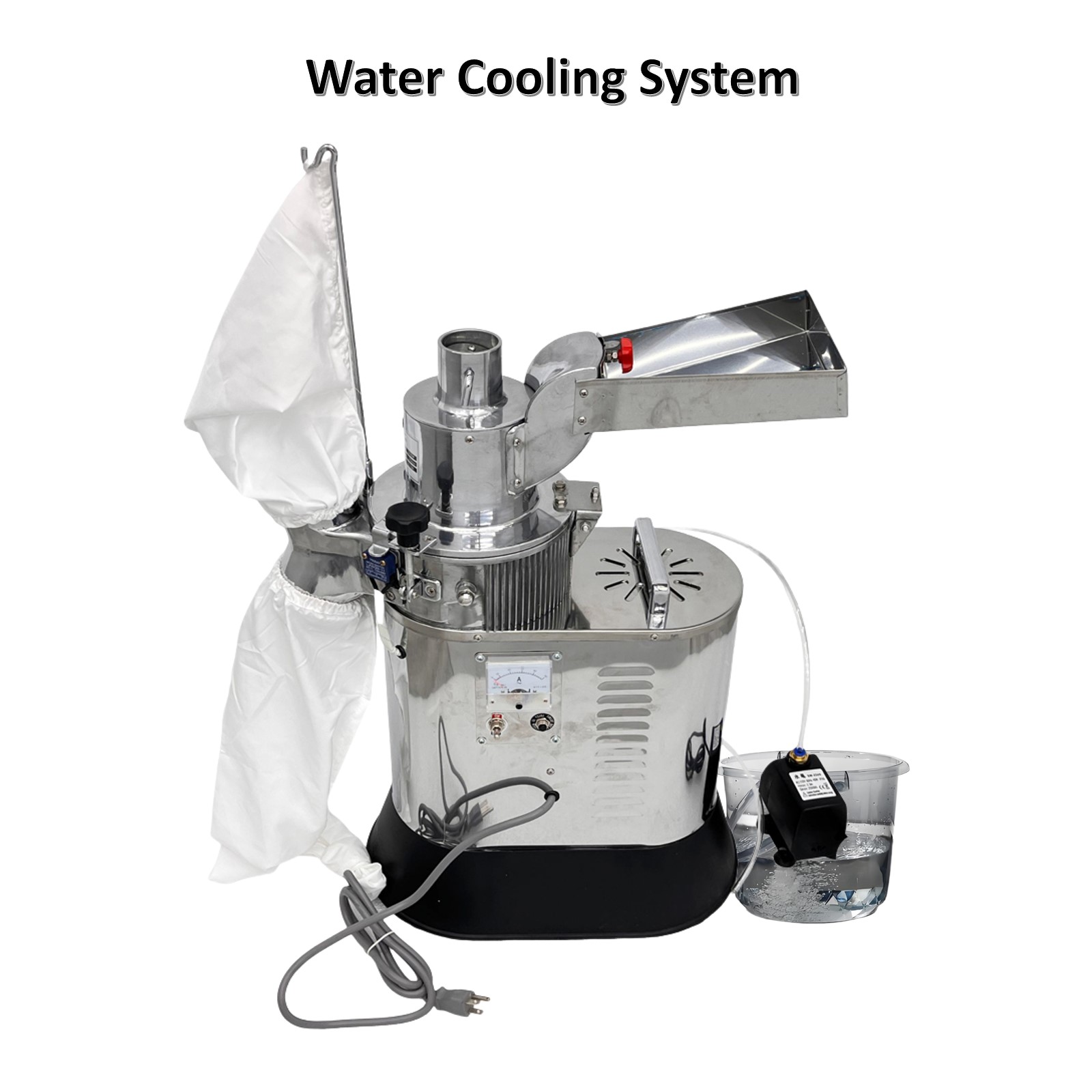

| The

grinder adopts the water cooling mode to improve the pulverizing

efficiency. The customer needs to prepare a bucket, and the water

pump can be put into the bucket and immersed in water. The cool

water in the bucket is pumped into the grinder so that the

grinding chamber can be cooled to reduce the temperature of

powder, and the motor can also be cooled to prolong the

continuous working time of the grinder. |

|

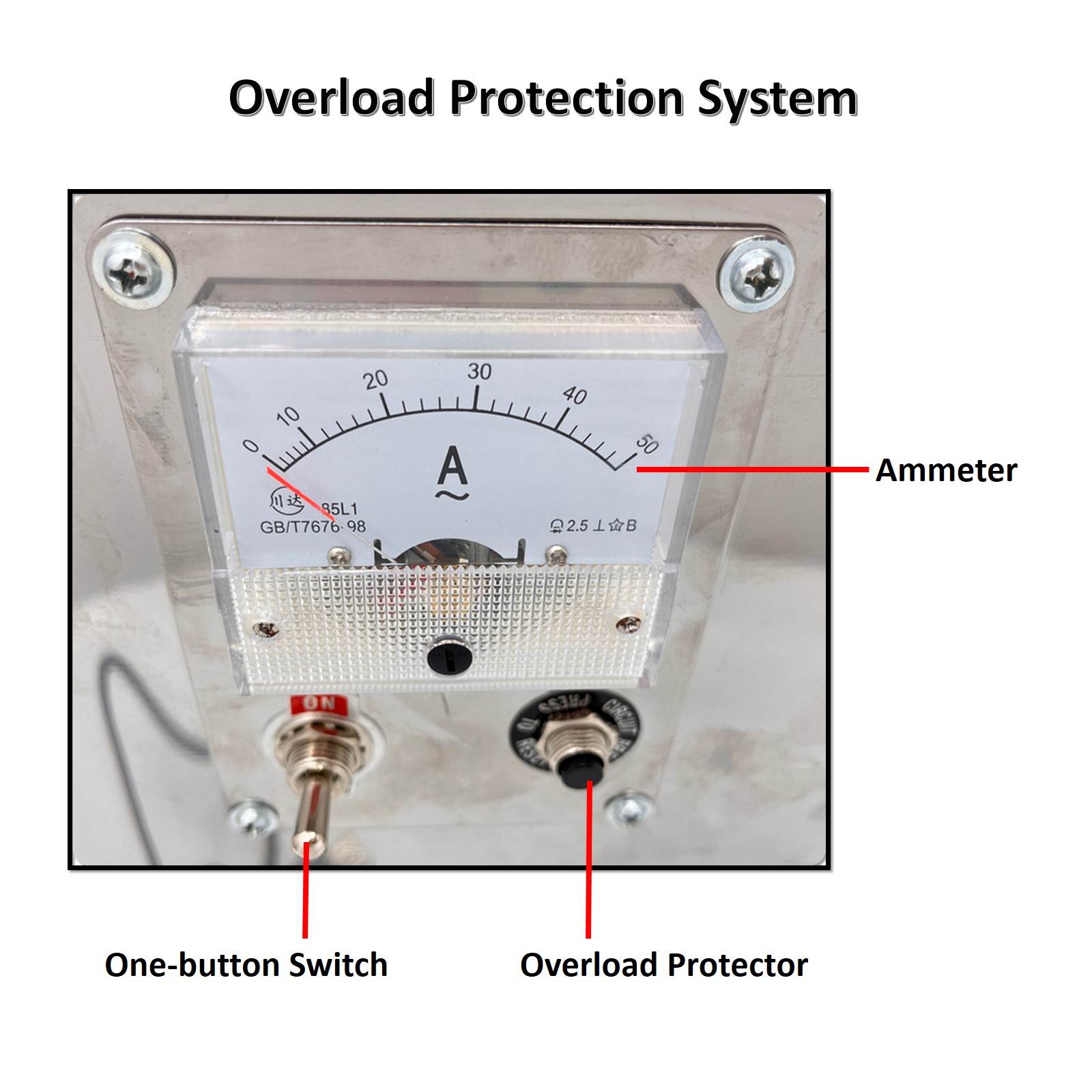

The ammeter, the

switch and the overload protector are integrated on the control

panel. When the current exceeds 10A, the operator can reduce the

feeding speed or stop feeding as needed. Automatic power off is

achieved when overload occurs, so that the operating safety is

ensured, and the motor is effectively protected against burnout.

The on/off operation is controlled by one switch, so that

operation is easy and convenient. |

|

|

|

|

|

| The

pure copper core high-power motor with the 3KW power is adopted,

thickened pure copper coils ensure the stable power and long

service life, the rotating speed can be higher, energy saving

and noise reduction are achieved, and the continuous operation

of the grinder can be well guaranteed. |

|

The grinder is

equipped with an enlarged stainless steel feeding hopper, the

feeding baffle can be adjusted up and down with the locking

bolt, so that the feeding speed will be adjusted as needed, the

adaptability and convenience are greatly enhanced, and the user

experience is higher. |

|

|

Operation

Method |

|

1. Install the feeding hopper in place.

Cover the outlets with the cloth bags well (the air outlet is covered

with the short cloth bag, and the powder outlet is covered with the long

cloth bag), hang the short cloth bag with the support rod, and knot the

other end of the long cloth bag.

2. Install the mesh screen according to the needs of fineness.

3. Put the water pump into the bucket and fill the bucket with water.

There are two water pipes coming out of the machine, one water pipe is

inserted into the water pump, and the other is put into the water in the

bucket. After connection, plug the power cord of the water pump into the

power socket, and the water circulation starts.

4. Connect the power supply, then turn on the power switch of the

grinder, and let the machine idle for one to two minutes before feeding.

5. The air inlet handle on the top of the air inlet can adjust the wind

speed.

6. The feeding speed should be slow, and the ammeter should be kept

within 10A.

7. After the powder is pulverized, do not turn off the machine

immediately, let the machine idle for about a minute to reduce residues.

8. Turn off the power switch, pull out the power cord, open the long

cloth bag, and pour out the powder.

9. Open the grinding chamber and take out the mesh screen. Use a brush

to clean the residue in the grinding chamber, clean the mesh screen and

dry it for the next pulverization.

|

|

Application |

|

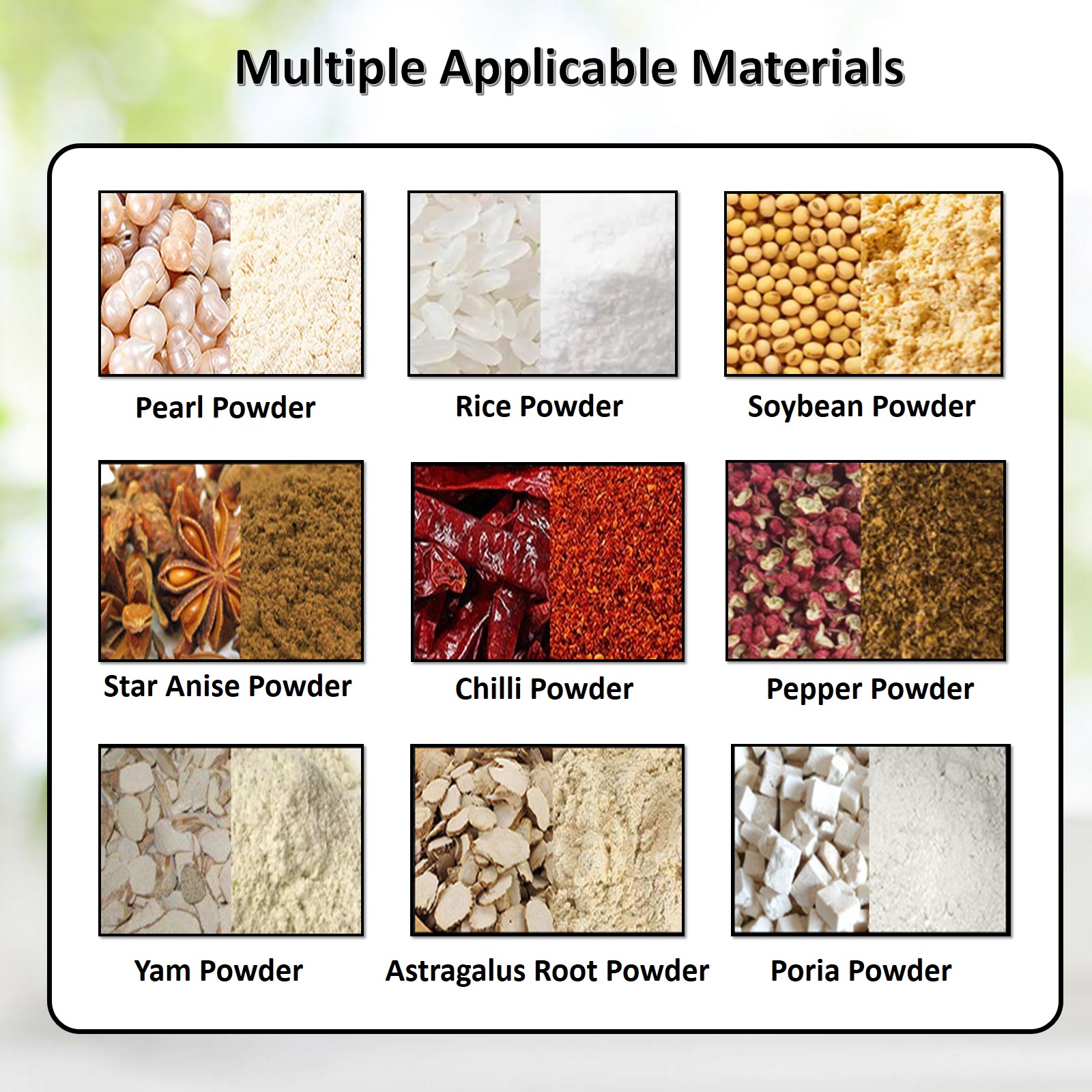

The water cooling type high-efficiency

grinder can grind various dry grain, seasonings and herbs, such as

pearls, rice, soybean, star anise, chillies, pepper, yams and poria, and

can be suitable for different application scenarios, such as food

factories, supermarkets, seasoning workshops, health clubs and bakeries.

It is an excellent grinder for customers. |

|

|

|

Product

Display |

|

|

|

.jpg) |

|

Item Number (170145): 1 x Water-Cooled

Continuous Feeding Grain Mill Grinder 110V 3KW |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|