|

|

|

Ultrasonic Plastic

Tube Sealer |

|

|

|

|

|

|

|

This machine working stability, high

efficiency. Stainless steel material could meet the corrosive products

of the end of the seal, once formed, sealing at the same time

automatically remove the excess edge. This machine is suitable for

toothpaste, cosmetics, food and other hose sealing. |

|

|

Product introduction: |

|

Ultrasonic plastic

tube sealing machine is suitable for toothpaste, cosmetics, medicines,

food industrial supplietc.

With horizontal aluminum alloy structure, stainless steel package,

environment friendly and sanitation.

With independent platform, vertical /horizontal adjustable worktable,

worktable, easy operation stable performance ,higefficiency. |

|

|

Product parameter: |

|

|

Power: 1200W

Voltage: 220V

Sealing diameter: 3.1inch (80mm)

Processing height: 7.87inch (200mm)

Weight: 140.8lb (64kg)

Size: 31.5*17.7*41.7inch (80*45*106cm)

Environmental

temperature : 0℃ +35℃

Environment humidity: relative humidity below 85%

Air pressure: 0.2----0.6 MPa

Ultrasonic working frequency:20k

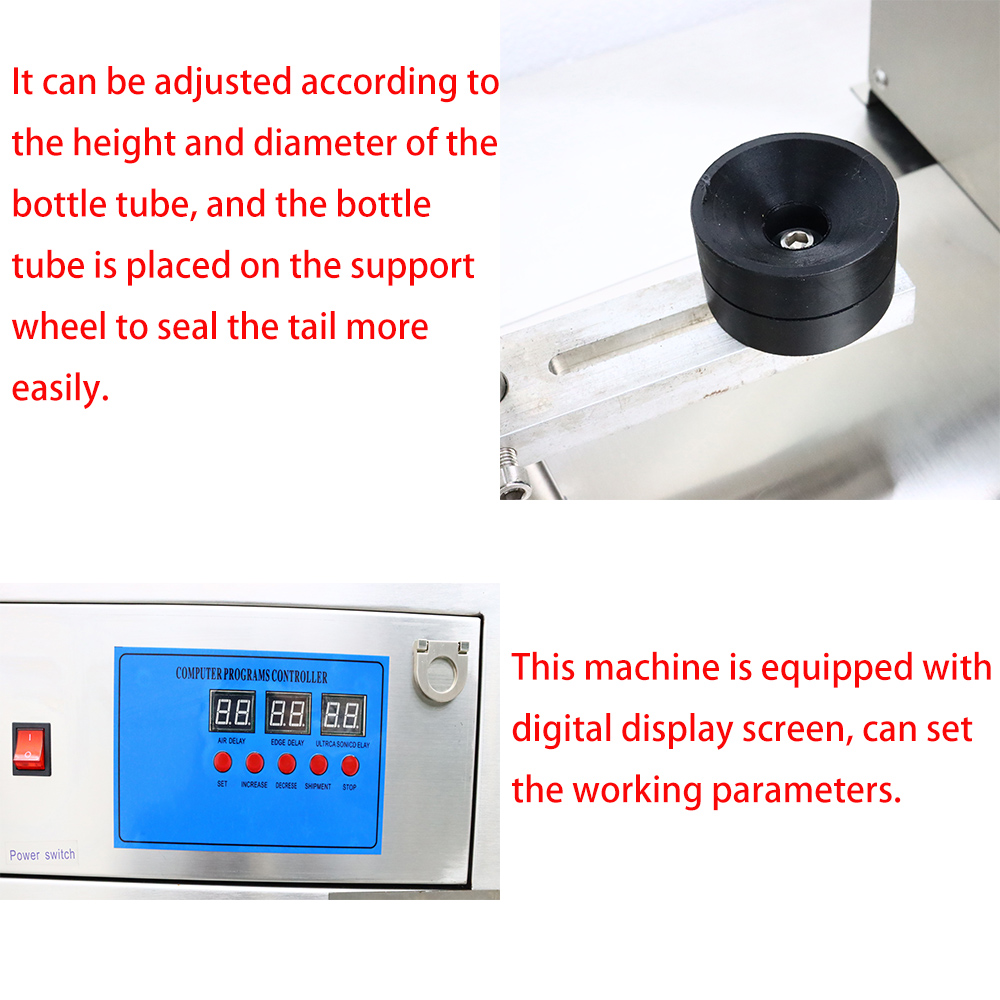

Tube height: 50~180mm (adjustable)

Tube diameter: F5~F50 mm (adjustable)

Removed more than expected : the edge of a straight line can be removed

move than expected

Working table: vertical/horizontal adjustable worktable |

|

Features: |

|

1.The use of advanced chips to make the machine

stability control.

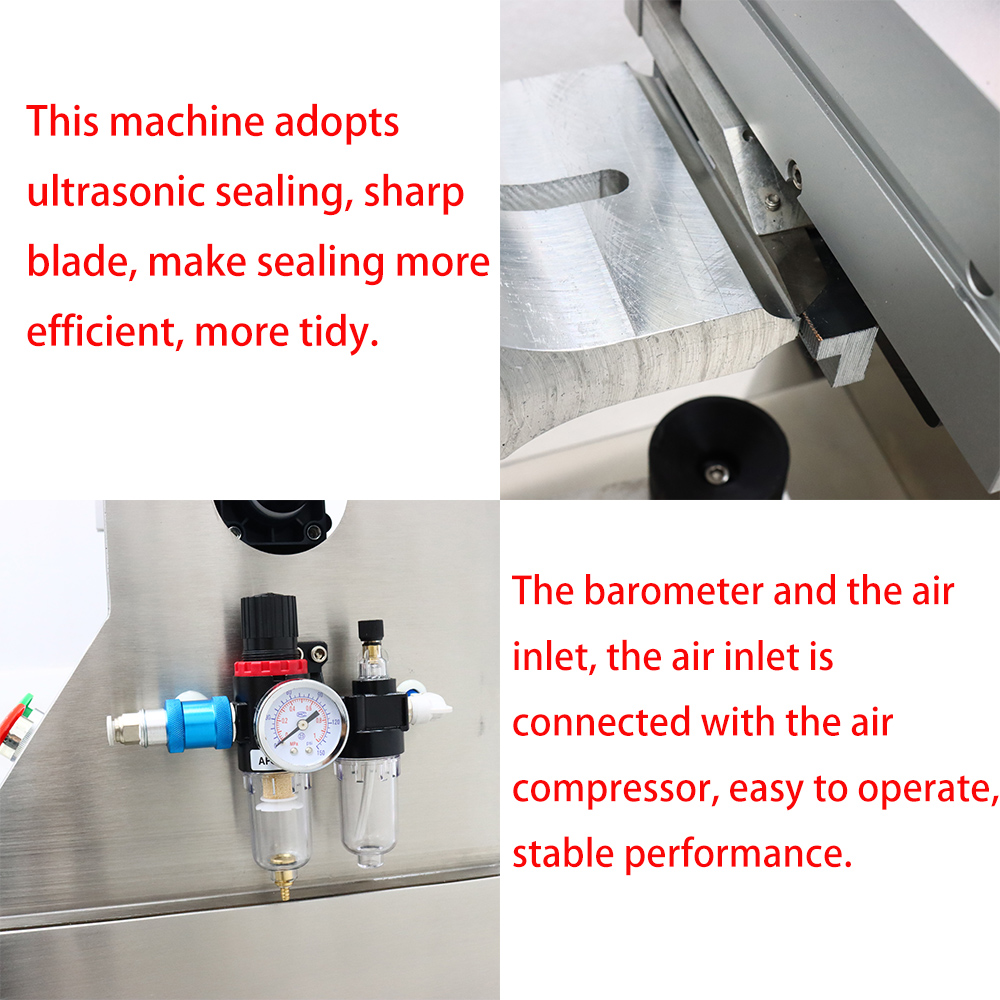

2.Sealing, trimming,

printing, once complete.

3.Sub-water care device can effectively

intercept a small amount of dust and fog.

4.Ultrasonic tool head is made of stainless

steel, it is sharp edge and durable.

5.Thicker material makes the machine more

durable.

6.This machine needs to

be used with air compressor (our machine does not include air

compressor). |

|

|

|

Product display: |

|

|

|

Product analysis: |

|

|

Product

safety precautions: |

|

1. The working

environment of the machine shall be dry, and an operator shall wear

plastic or rubber shoes;

2. The transducer system shall not be dismounted and replaced when the

machine is switched on;

3. Do not put two hands below the tool head to prevent the hands from

being injured through ultrasonic waves in case of ultrasonic wave

generation during working or test of the machine;

4. The welding die shall not be in direct contact with the base or the

metal clamp of the machine in working or test;

5. High-quality ventilating equipment shall be arranged in the operating

acoustic field when plastic workpieces with odors are processed;

6. During operation, operation shall be immediately stopped in case of

abnormal noise or that the transducer system is heated to 50 DEG C or

even higher, and the operator shall test the working frequency of the

machine and check whether the machine is normal;

7. Do not switch on the machine immediately after a broken fuse of the

machine is replaced, and the machine cannot be switched on until a

trained technician checksrelevant parts of the machine to confirm that

other faults do not exist in order to avoid extension of the fault;

|

|

Note:

1.Do not turn on the machine before placing any

operating materials, it will burn the fuse.

2.Our

machines are always used on the first gear when they leave the factory.

If customers shift to the second and third gears, they must first check

the ammeter. If it is higher than 1, they must adjust the frequency

screw to reach 1 before it can work, otherwise it is easy to burn out

the power tube.

|

|

Details: |

|

|

|

|

Item included:1*Ultrasonic

Plastic Tube Sealer |

|

Item Number: 239406 |

|

|

You can make

order with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|